RC Continuous Beam Bridge Reinforcement

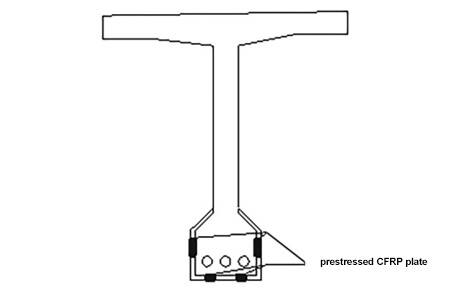

Prestressed Carbon Fiber Reinforcement

The overall stiffness and durability of the bridge have been significantly improved, and prestressed carbon fiber plate reinforcement can effectively treat bridge crack diseases, suppress the development of new cracks, and extend the service life of the bridge.

A national highway crossing bridge was completed and opened to traffic in 2014, with a total length of 165m. The upper structure adopts a 5 * 30m prestressed reinforced concrete continuous T-beam, the bridge deck is paved with asphalt concrete, and the bearings are made of rubber bearings; The lower structure consists of an expanded foundation for the U-shaped abutment, a pile foundation for the ribbed slab abutment, and column piers. The design load of this bridge is Class A and the design speed is 80km/h. Due to its long service life, heavy traffic flow, and heavy axle loads, this bridge has caused cracks in the main beam web, bottom, and other areas, posing a serious threat to the safety of bridge operation. Therefore, it is urgently needed to repair and reinforce the reinforced concrete continuous beam bridge.

Bridge reinforcement plan

Considering the serious damage to the main beam of the bridge, the management and maintenance unit originally planned to adopt a comprehensive treatment plan of replacing the main beam. However, considering that replacing the main beam requires the construction of the road to be completely closed, and the construction period for replacing the main beam is too long, which will have a serious impact on the normal traffic of the road, the management and maintenance unit decided to change the original replacement main beam plan to a maintenance and reinforcement plan.

In recent years, prestressed fiber reinforcement technology has been widely used in bridge reinforcement engineering, combining the advantages of bonded fiber reinforced composite material reinforcement method and external prestressed reinforcement method. Not only can it effectively overcome the disadvantage of fiber material stress lag in the reinforcement of structures by pasting fiber reinforced composite materials, ensure the integrity and collaborative work of fiber materials and structures, but it can also continue its lightweight, high-strength, corrosion resistance, fatigue resistance, and strong designability characteristics. After comparing and selecting various reinforcement methods, this project ultimately adopts prestressed carbon fiber reinforcement technology with excellent reinforcement effects.

In order to further clarify the technical status of the bridge in this project, the construction unit conducted static and dynamic load tests on the prestressed carbon fiber plate before and after reinforcement. The test results indicate that before the carbon fiber plate reinforcement, the overall bearing capacity of the bridge in this project still meets the design load requirements; The mid span cracks of the beam showed some expansion during the static load test before strengthening with carbon fiber plate. However, after unloading the load, all cracks were basically restored to their original state, while the mid span cracks after strengthening with carbon fiber plate reached a closed state, and no new cracks appeared during the static load loading process;

The overall stiffness and durability of the bridge have been significantly improved, and prestressed carbon fiber plate reinforcement can effectively treat bridge crack diseases, suppress the development of new cracks, and extend the service life of the bridge.