Bridge Structural Cracks

Carbon Fiber Structural Reinforcement

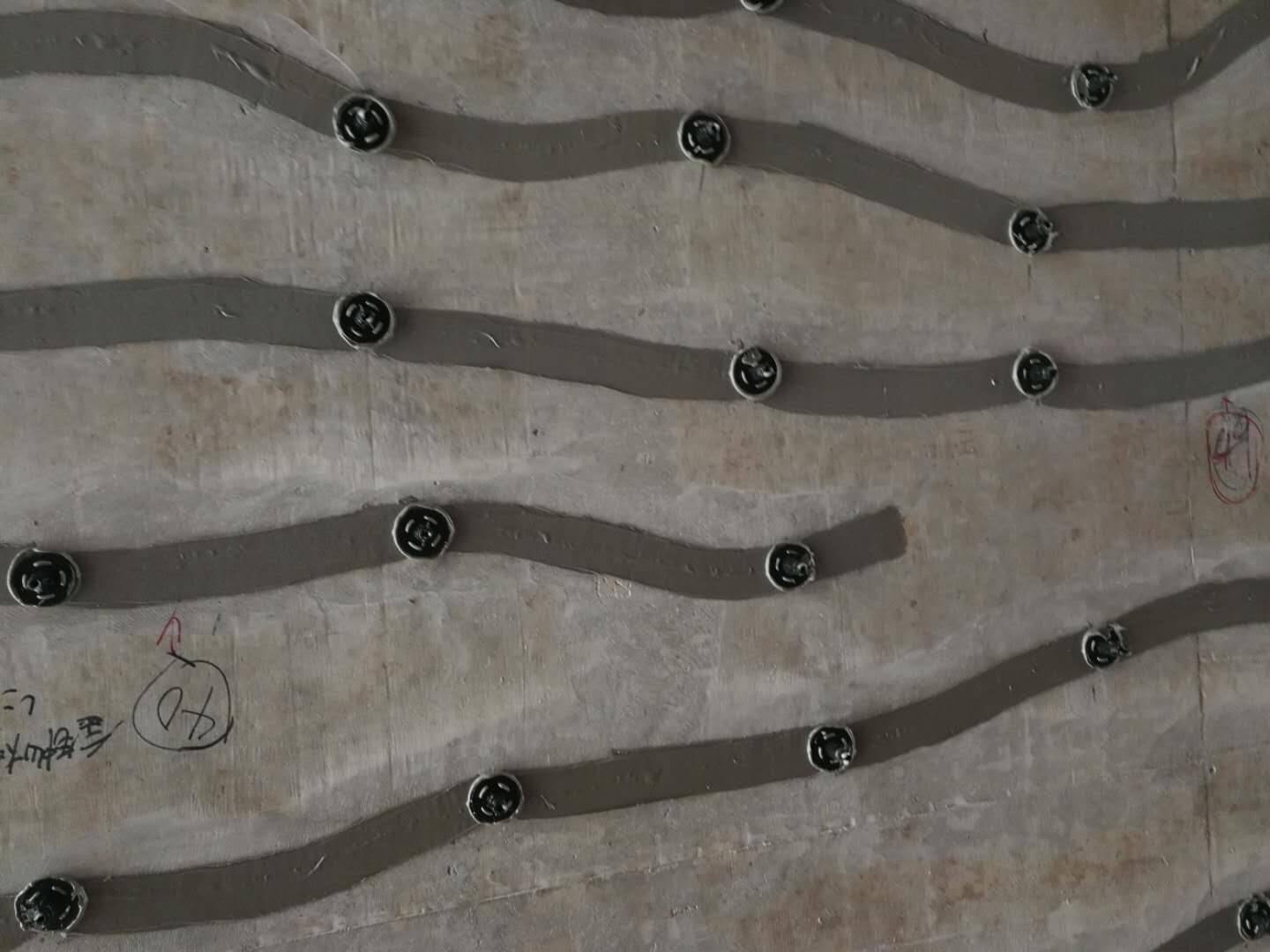

In order to improve the service life of the bridge box girder, and then improve the overall bearing capacity of the bridge, the bottom of the box girder is covered with carbon fiber cloth for reinforcement.

Fenglingdu Yellow River Highway Bridge

Bridge

The bridge has a total length of 1410 meters, a width of 12 meters, a pier height of 20 meters, and a span of 114 meters for the main bridge. The bridge's foundation was laid in April 1992, and it was completed and opened to traffic in November 1994.

The upper structure of the main bridge adopts three-way prestressed concrete variable-section continuous box girder, the lower structure adopts hollow thin-walled pier, and the foundation is drilled and poured into the foundation. The net height of the bridge deck is 8m and the net width is 44m. The extra-large bridge was completed and opened to traffic at the end of 994. Since its operation, it has been repaired and strengthened for many times. The inner beam section of the web at the beam end has been reinforced with concrete, cracked, and prestressed in the body. Steel box arch is used to improve the side span stiffness.

During the operation and use of the bridge, an investigation was carried out on the bridge structure, and it was found that there were many transverse cracks and longitudinal joints on the bridge deck, local rutting, subsidence and other diseases, bridge joint damage, pier exposed ribs and other diseases. Among them, the bridge structure is relatively cracked, and the bridge structure needs to be reinforced.

Bridge disease

a) The bridge deck has transverse cracks and longitudinal cracks in many places on the bridge deck pavement, and block cracks are locally distributed, and ruts and depressions appear in individual positions.

b) The diseases of the bridge superstructure mainly include 5 cumulative damages of the box girder joints, 1.35 m2 of exposed reinforcement on the bottom of the box girder, 14 m of water seepage and whitening cumulative length, and 0.55 m2 of concrete shedding in the mid-span of the box girder.

c) The structural diseases of the lower part of the bridge include the accumulation of 1.05 m2 of exposed ribs from the cover beam, and the weathering damage of the bridge pier block. In addition, part of the main girder and cover girder of the bridge was damaged and missing, some box girder girder bodies were damaged due to rain erosion, individual reinforced concrete members were corroded, and a large number of cracks were distributed on the upper part of the girder body.

Analysis of Causes of Bridge Cracks

a) The joint position of the beam body is damaged due to vehicle load, and cracking damage occurs at the joint position. Since the cracks were not repaired in time, rainwater penetrated into the bridge structure, causing further cracking and damage to the bridge structure.

b) The natural frequency of the bridge is close to the frequency generated by the vibration of some vehicles, which causes resonance of similar bridge vehicles and damages the bridge structure.

c) After the longitudinal cracks of the bridge are generated, the compressive capacity of the bridge structure is reduced, and the generation of transverse cracks is accelerated under the action of vehicle loads.

Bridge Maintenance and Reinforcement Scheme

Combined with the disease investigation of the Fenglingdu Yellow River Highway Bridge, a reinforcement plan was formulated to reinforce the cracks on the bridge deck and the upper part of the box girder. During the investigation, it was found that some bridge joints had been damaged, resulting in longitudinal penetration cracks. In order to ensure the safety of the bridge structure, the bridge deck pavement was removed, rebars were planted in the bridge deck structure, steel mesh was re-arranged, C40 steel fiber reinforced concrete was built around it, and finally a 3~4cm fine-grained asphalt concrete abrasion layer was paved.

Combined with the practice of bridge preventive maintenance, there will be some cracks of more than 0.15mm in each span of the bridge box girder every year, and the cracks have a trend of continuous development. The new cracks are usually repaired by maintenance methods such as grouting and sealing, but new cracks or original cracks are damaged every year. The analysis is caused by insufficient tensile strength and elastic modulus of the beam. In order to improve the service life of the bridge box girder, and then improve the overall bearing capacity of the bridge, the bottom of the box girder is covered with carbon fiber cloth for reinforcement.