Beams And Slabs Reinforcement

Carbon Fiber Large-scale Reinforcement

The structural reconstruction and reinforcement of this commercial secondary reconstruction project adopts the carbon fiber reinforcement method, which not only improves the construction efficiency but also saves the reinforcement cost.

Project Description

This project is a commercial secondary decoration and renovation project. The main structure is a frame structure, with two floors underground and six floors above ground. The overall reconstruction area is 222463.36m2, the above-ground reconstruction area is 172520.3m2, and the underground reconstruction area is 49943.06m2. The main reinforcement objects of this renovation project are the columns, beams and slabs of the original structure. This commercial secondary renovation project requires a total carbon fiber reinforcement area of 26,205m2.

Comparison of reinforcement schemes

At present, the more commonly used reinforcement methods for concrete structures, such as increasing the section, external prestressing, sticking rigidity, glass fiber reinforced plastic sticking, and spraying concrete, have their own advantages and disadvantages. These traditional reinforcement methods not only increase the weight of the original structure, but also suffer from problems such as chemical corrosion. The method of reinforcing beams, slabs, columns and shear walls of old buildings with carbon fiber can well avoid the above problems. The method of carbon fiber reinforced concrete structure is to use epoxy resin to glue the surface of the building structure to be reinforced with carbon fiber cloth to make it an integral structure. Carbon fiber reinforcement not only has high strength, but also greatly improves construction efficiency, and has the advantages of light weight, small size, and easy construction. Carbon fiber reinforcement can not only improve the structural strength but also have great benefits in preventing the further expansion of cracks.

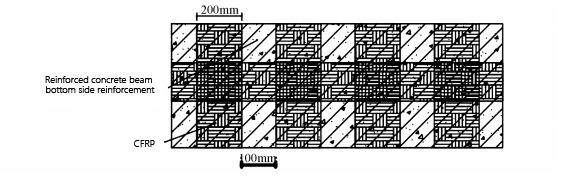

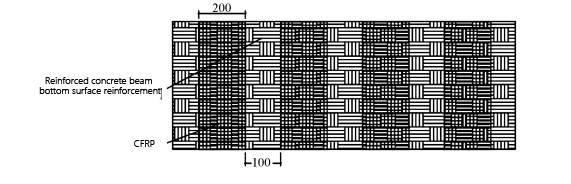

Comparing the effects of various reinforcement methods, it can be seen that the carbon fiber reinforcement method is more suitable for this commercial secondary reconstruction project. Therefore, an economical and efficient carbon fiber reinforcement method was finally selected to reinforce the beams and slabs of a project in Shenzhen. The carbon fiber reinforced beams and slabs are all reinforced with a tensile strength standard value of 3400MPa, a thickness of 0.167mm, and a model of 300g/m2 carbon fiber cloth to reinforce the original beams and slabs of this renovation project. The main adhesive materials required are base glue, epoxy mortar and adhesive resin.

The enlarged cross-section and bonded steel reinforcement methods have higher requirements on the surrounding construction space, and the method of enlarged beam cross-section also requires scaffolding at the bottom of the beam for support. At the same time, the original slabs on both sides of the beam to be reinforced also need to be removed. The column-clad steel reinforcement method also requires the removal of the original walls on both sides of the column, and the removal of the adjacent electromechanical equipment is more complicated and the reinforcement time is long.

1) The structural reconstruction and reinforcement of this commercial secondary reconstruction project explores the large-scale use of carbon fiber reinforcement to reinforce the original concrete structure.

2) The structural reconstruction and reinforcement of this commercial secondary reconstruction project adopts the carbon fiber reinforcement method, which not only improves the construction efficiency but also saves the reinforcement cost.

3) The reinforcement effect of strip-shaped carbon fiber cloth is better than that of full carbon fiber cloth, and it also saves materials and construction costs.

4) The use of carbon fiber reinforcement is more convenient for the construction of the renovation project, and there is less conflict with other professional mechanical and electrical construction.

5) There are many problems in the reinforcement construction process of carbon fiber reinforced beams and slabs that need to be paid attention to, otherwise it will have a greater impact on the reinforcement effect. If the adhesive surface in the early stage of reinforcement is not cleaned or the finished product is not protected in the later stage of reinforcement, the reinforcement effect will be greatly reduced.