In-service Reinforced Concrete Bridge Strengthen and Reconstruct

Bridge Strengthening and Repair

After reinforcement, the purpose of improving the bearing capacity is achieved, the reinforcement cost is relatively small, and the appearance of the original bridge can be maintained

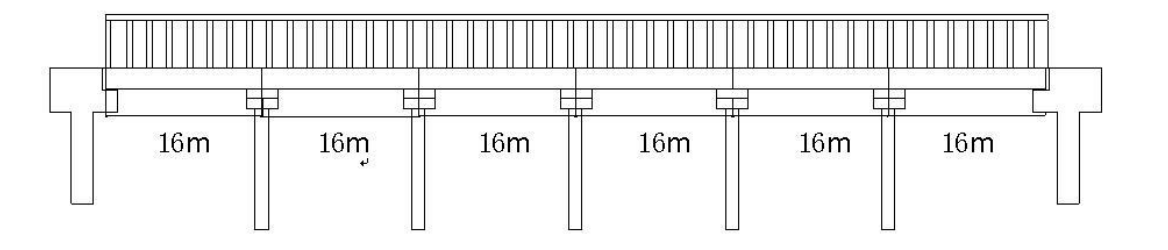

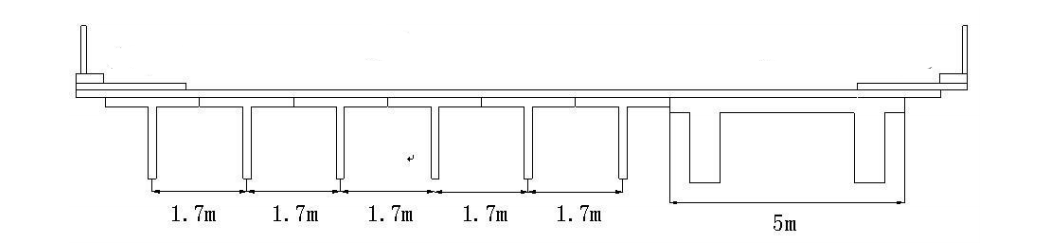

The upper structure of the old bridge with a total length of 100m and a span of 6×16m is a simple concrete T-beam. The upper structure of the old bridge is a simple concrete ∏ beam. The bridge has a width of 14m, of which the old bridge has a width of 5∙0m in the upstream and the new bridge has a width of 8∙5m in the downstream. The lower structure of the old bridge adopts the form of two pier column foundations as the enlarged foundation. The lower structure of the new bridge adopts the form of pile-column structure. The pier column is composed of two concrete columns with a diameter of 100 cm. The pile foundation adopts 2 bored piles with a diameter of 120 cm.

The results of the implemented bridge inspection show that:

The vertical and diagonal cracks on the surface of the new and old main beams of the bridge have developed severely. Some main beams have vertical cracks that penetrate the upper and lower main beams, and the rigidity of the bridge has been significantly reduced. The main girder of the bridge needs to be strengthened or reinforced in bending and shear.

The bridge deck has many cracks, potholes and other disease expansion joints that need to be dealt with.

The concrete of the piers of the bridge piers under water hollowed out columns has fallen off and exposed bars, which need to be reinforced.

Therefore, the bridge has potential safety hazards and needs to be reinforced or enhanced.

Elevation view of the bridge

Cross-sectional view of the bridge

Reinforcement and transformation plan of the superstructure

For the various cracks found in the bridge inspection, the method of pouring epoxy mortar is used to seal the cracks. For diseases such as exposed bars found in various parts of the bridge, epoxy resin is used to smear the surface of exposed steel bars to achieve protection.

The bridge deck system shall be re-paved or modified.

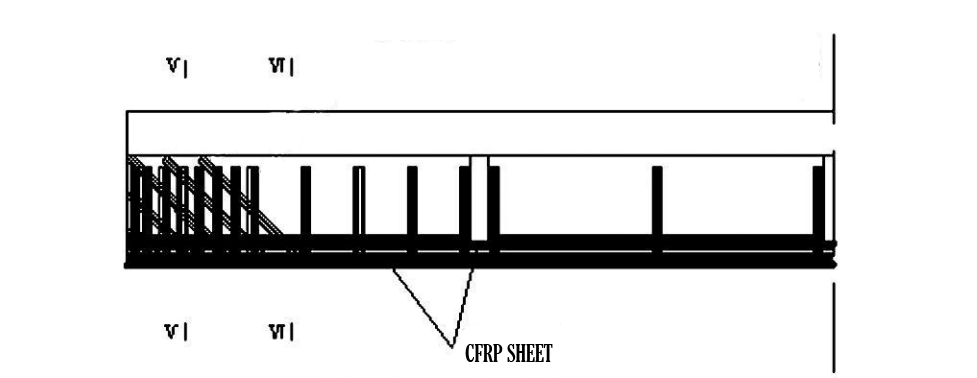

Reinforcement plan for the main beam of the bridge simply supported T-beam

Fiber sheet reinforcement method

By sticking high-strength, high-elasticity fiber sheets to the outer surface of the T beam, the load-bearing capacity of the bridge can be enhanced or improved. Fiber sheet (fiber sheet or fiber cloth), the thickness is about 0∙11-0∙43mm, the number of sticking layers is 1-3 layers). This reinforcement plan intends to use imported carbon fiber raw silk material, its tensile strength is about 10 times that of steel bars, and its elastic modulus is about 1∙2 times that of steel bars. The unit weight is only about 1/5-1/4 of the steel, and it is resistant to acid and alkali corrosion, has excellent durability, and has a good interface with concrete.

Advantages: The cost of bridge reinforcement is low, which can effectively improve the load-bearing capacity of the bridge, and hardly increase the weight and size of the bridge. The construction period is short and no large-scale construction equipment is required. After reinforcement, the maintenance cost of the bridge is extremely low.