Strengthening Of Bridges

Externally Prestressed Carbon Fiber Strip

After the bridge was strengthened and used for 1 year, after two inspections and evaluations, the box girder conformed to the expected reinforcement effect of the design, and the bending and shearing capacity met the load standards required by the current code.

Project Overview

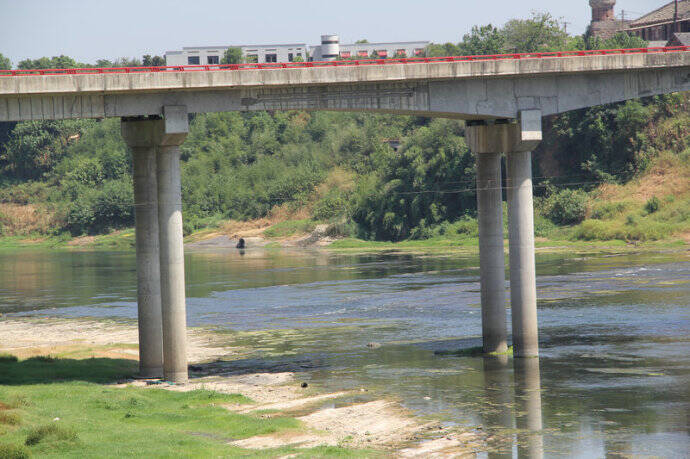

The Zhujindu Bridge is located on the 320 National Road across the Lianshui River about 8km west of Xiangxiang City, Hunan. It was completed and opened to traffic in 1999. It is a prestressed concrete variable cross-section single-box double-chamber continuous box girder bridge with a total length of 306.24m, a total of 9 spans (2×30+2×50+4×30+20)m, and a maximum span of 50m. The design load rating of the bridge is car-20. In 2012, there were more bending and shear cracks at the quarter point of the box girder of the bridge, and there were more structural cracks in the mid-span with insufficient mechanical performance of the transverse frame, and the bridge deflection became larger. After testing, it was found that the bending and shearing strength of the bridge was insufficient, and the stiffness was too small. It was identified as a fourth-class dangerous bridge and must be reinforced in time.

Due to space limitations, this article only introduces the use of fixture anchors to strengthen the beam with external prestressed carbon fiber plates and improve its bending resistance.

External prestressed carbon fiber reinforcement measures

The reinforced concrete box girder of the bridge is strengthened by using special fixture anchors for external prestressed carbon fiber strip technology to improve the flexural bearing capacity and flexural rigidity of the bridge.

In the positive bending moment area, the reinforcement is adopted on the bottom surface of the box girder or the inner and outer webs of the box girder with a straight base surface, and the negative bending moment area is reinforced by external prestressed carbon fiber strip under the bridge deck pavement.

Mid-span positive bending moment zone

(1) Variable cross-section span: The external prestressed carbon fiber strip is tensioned and reinforced on the box girder web in the middle of the span. A total of 28 prestressed carbon fiber panels with a width of 10 cm are arranged.

(2) Constant cross-section span: Tensile reinforcement of prestressed carbon fiber strip on the bottom surface of the box girder bottom plate. Arrange 5cm and 10cm wide prestressed carbon fiber strips with 20 channels each.

Negative bending moment area (support position)

The prestressed carbon fiber strip is used to reinforce the top surface of the box girder top plate. A total of 8 prestressed carbon fiber panels with a width of 10 cm are arranged.

Carbon fiber strip

1.2mm 100mm and 50mm

Concluding remarks

After the bridge was strengthened and used for 1 year, after two inspections and evaluations, the box girder conformed to the expected reinforcement effect of the design, and the bending and shearing capacity met the load standards required by the current code. The bending-shear cracks closed by grouting during the beam reinforcement and the structural cracks with insufficient force performance of the transverse frame at the mid-span did not appear abnormal, and no new cracks appeared, and the beam deflection tended to be normal.