Main Structure Of The Hotel Strengthening

Carbon Fiber And Bonded Steel For Strengthening

(1) Reinforce the foundation and foundation beams. (2) Repair and strengthen the damaged frame column. (3) Repair the damaged main beam of the frame and reinforce it with carbon fiber. (4) Repair damaged floors and stairs and stick carbon fiber reinforcement.

The main security reinforcement content of the SF Hotel Project

(1) Reinforce the foundation and foundation beams.

(2) Repair and strengthen the damaged frame column.

(3) Repair the damaged main beam of the frame and reinforce it with carbon fiber.

(4) Repair damaged floors and stairs and stick carbon fiber reinforcement.

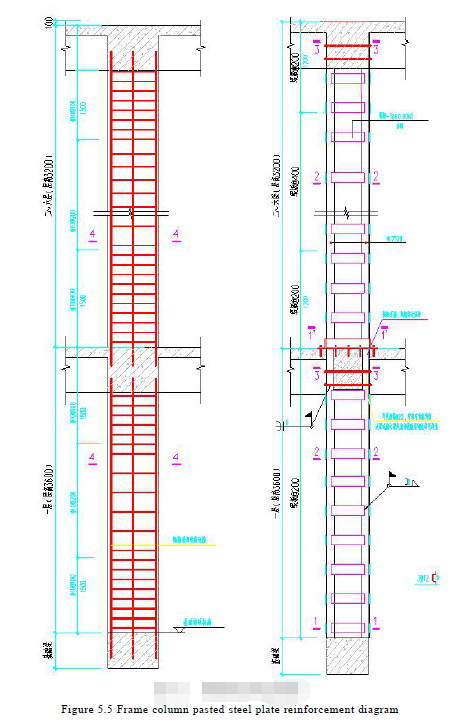

Column reinforcement

(1) Column reinforcement method and material selection

After all the frame columns are repaired this time, the full-height hoop steel-clad reinforcement method is adopted by the outer steel reinforcement method.

In terms of material selection, the steel plate is made of Q235B steel (No. 3 steel), and the specification of the section steel is L75X8. When the longitudinally stressed steel bars of the frame with seismic resistance class 1, 2, and 3 are ordinary steel bars, the measured value of tensile strength and the measured value of yield strength of the steel bars should be controlled within 1.25. The standard value of the yield strength and the measured value of the yield strength should be lower than 1.3, and the measured value of the total elongation of the steel bar under the maximum tensile force should not be less than 9%. The width of the battens is 100mm, the thickness is 80mm, and the spacing between the battens is 200/400mm. The frame column repair and reinforcement use high-strength structural glue to paste HM-120.

Before reinforcement, most of the live load acting on the beam is removed. The surface of the original column and beam is chiseled off by 10mm-15mm, and the edges and angles are shaved. The new and old concrete joint surface is poured with pure cement slurry before casting the old concrete surface. Chisel off the protective layer of the welding length range of the main reinforcement at the lower part of the reinforced concrete beam and the beam side stirrup (single-side welding range) to expose the surface of the main reinforcement and the welded stirrup and the original beam longitudinal reinforcement at the welding point of the connecting short reinforcement exposes half of its diameter . The concrete joint surface of the non-welded steel bar shall be chipped off, and all fragments and scum shall be removed and rinsed with water. Rebar welding adopts segmented, layered, symmetrical, and jump welding methods. The length of the single-side welding seam is 10d, the length of the double-side welding seam is 5d, the height of the main reinforcement welding seam is 6mm, and the height of the stirrup welding seam is 5mm.

Before pouring the high-strength grouting material, the surface of the original beam should be watered 24 hours in advance, and the cement paste should be brushed in strict accordance with the proportion of 1:0.4. In order to facilitate the pouring, an oblique opening on the formwork is equipped with a horn pouring and tamping opening, which is about 100mm higher than the old concrete. When the reinforced concrete reaches C15, the protruding parts on the side of the beam are removed.

The reinforced longitudinal reinforcement at the bottom of the beam should be drilled and planted into the original reinforced concrete column, and anchored with anchoring agent.

After the glue is poured, the reinforcement process needs to be implemented, and the newly added concrete should be covered and insulated in time and watered for curing. The curing time should reach 14 days and keep it in a wet state.

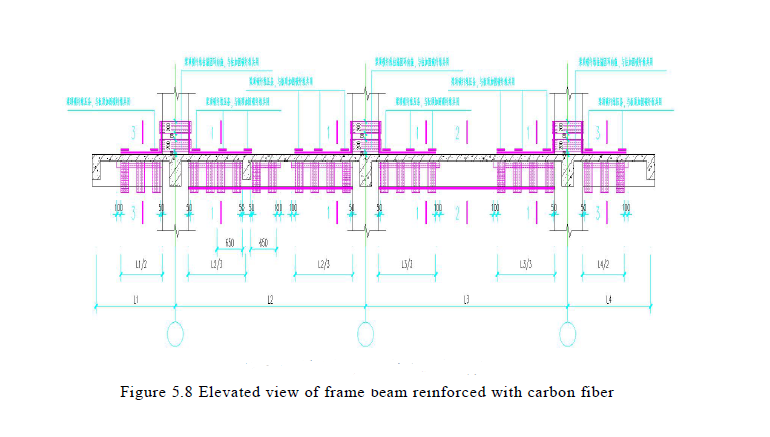

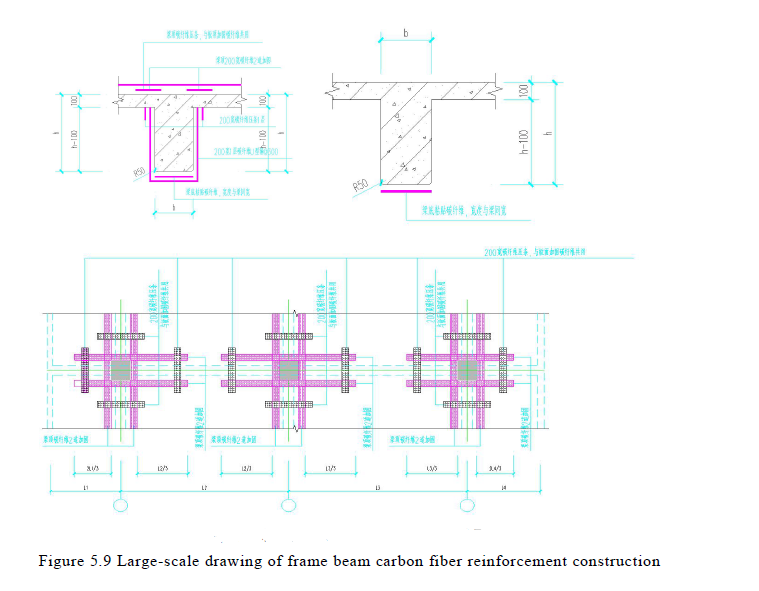

Reinforcement of beams and slabs

(1) Beam reinforcement method and material selection For beam reinforcement, the use of pasted carbon fiber cloth is used for reinforcement. Using high-strength grade I, 300g carbon fiber cloth, the expansion rate is not less than 1.7%, the elastic mold is not less than 240GPa, the thickness is 0.167mm, and the standard duty of tensile strength needs to be not less than 3400MPg. The carbon fiber adhesive uses grade A glue that matches the carbon fiber cloth.

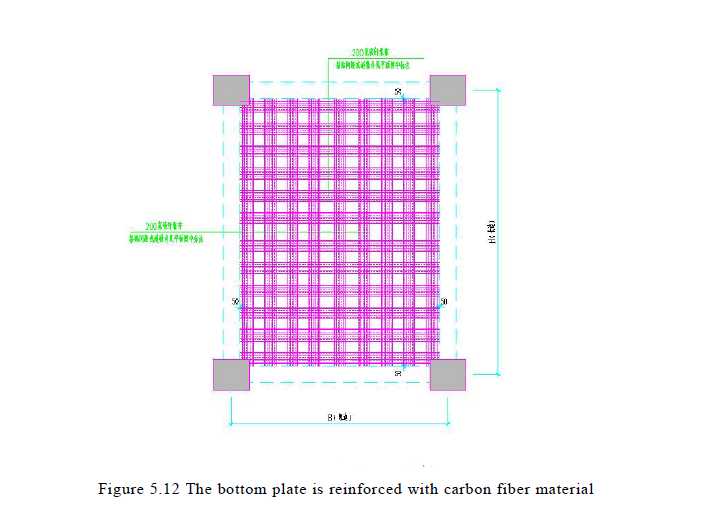

(2) Plate reinforcement method and material selection

The board reinforcement also chooses the method of pasting carbon fiber cloth