Bridge Crack Repair

Carbon Fiber Reinforcement Technology

By using carbon fiber reinforcement technology to reinforce the reinforced concrete hollow slab of the bridge, it shows that after the reinforcement, the dynamic performance of the bridge is effectively improved, and the cracks of the bridge are effectively repaired.

Project

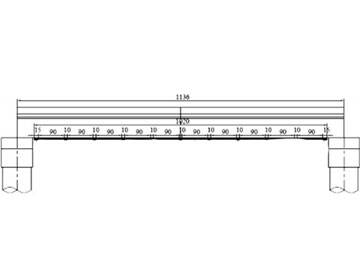

After a certain expressway was put into operation for a period of time, due to the rapid growth of local traffic and heavy vehicle load, many cracks appeared in the bridge deck pavement and slab bottom during the use of the bridge. The bridge is designed with two left and right open to traffic, each with 19 spans. The two left and right bridges are newly built bridges, the upper structure adopts reinforced concrete hollow slab structure, and the lower structure adopts pile-column piers. The layout of the left and right bridges is detailed in the figure. The design load of the bridge is steam-20 and hanging-100; the left bridge skew angle is 12°, the right bridge skew angle is 0°; the bridge span combination is 19×15.4m; the total bridge deck width is 21m.

Disease investigation

During the operation and use of the expressway, due to the influence of vehicle load and climatic factors on the bridge structure, daily investigations revealed that the bridge had many diseases. Among them, cracks are the most serious.

Through detailed on-site investigations, the bridge deck pavement, slab bottom, cap beam and other parts appeared many diseases, and there were water seepage and concrete damage at the beam ends, hinge joints, and spans. Through detailed appearance inspection, the following problems were mainly found:

(1) A large number of cracks were found in the pavement layer and the bottom of the bridge deck, mainly longitudinally cracking along the hinge joints, and there is a trend of further expansion, and reinforcement treatment is required.

(2) There are concrete damage, steel rusting, and a large number of cracks in the middle of the bridge and the beam ends, which will have a great impact on the stability of the bridge structure.

(3) There is water seepage at the hinge joints of the reinforced concrete hollow slab of the bridge, resulting in the phenomenon of corroded expansion and bar exposed in the cover beam, which will have a certain impact on the bearing capacity of the bridge.

The basic principle of carbon fiber reinforcement

Using carbon fiber reinforcement technology, epoxy resin material is first applied to the surface of the concrete structure for pasting carbon fiber cloth. The resin and the materials inside the concrete combine to form a bonding substance, which combines the carbon fiber cloth and the concrete as a whole, which strengthens the bridge structure. Carbon fiber cloth has high strength and elastic modulus, which can effectively make up for the insufficient tensile strength of reinforced concrete structures. In addition, when the carbon fiber cloth is subjected to temperature stress, the temperature stress generated is much smaller than its ultimate strength (3400MPa), and the effect is small. The carbon fiber cloth is pasted on the tensile surface of the reinforced concrete hollow slab structure of the bridge to form a whole with the bridge structure and jointly bear the external force, which can effectively reduce the stress of the steel bar, effectively suppress the cracks, and strengthen the bridge structure.

Key points of construction technology for carbon fiber reinforcement

Formulate a carbon fiber reinforcement plan

The cracked parts of the bridge in this project are mainly concentrated on the pavement of the bridge deck, the bottom of the beam and the hinge joints. Combined with the damage of the bridge components, epoxy resin and carbon fiber cloth are selected according to the construction requirements, and the quality inspection is carried out. All indicators can be used only if they meet the requirements. . It is designed to paste carbon fiber cloth on the bottom of the hollow board, and paste carbon fiber cloth bead on the two carbon fiber cloth joints. According to the investigation of the damage of the bridge, the focus is on the reinforcement of the mid-span position of the bridge. The specific reinforcement plan is shown in Figure 1.

Surface treatment of reinforced concrete components

If there are defects on the surface of the reinforced concrete members of the bridge, clean up all the brittle cracks and loose parts. The exposed steel bars are treated with rust prevention, and the cracks on the concrete surface are repaired. The cracks with a width of 0.20mm or more are repaired with epoxy resin. The cracks below 0.20mm are treated with epoxy resin.

Grassroots treatment

Use mortar that is stronger than the concrete of the bridge structure to repair the damaged parts and ensure that the surface of the structure is flat and clean. The surface of the reinforced part shall be polished, and the concrete surface shall be thoroughly cleaned after polishing to ensure the paste effect.

Apply the bottom interface agent

Apply TP epoxy resin on the surface of the treated concrete structure, and the resin penetrates into the concrete structure and combines with the concrete as a whole, and bears the force together.

Repair of surface defects of concrete components

If there are still partial defects on the surface of the concrete component after the bottom interface agent is applied, use epoxy putty to repair the defect. After the repair is completed, use sandpaper to polish the rough lines and fine particles on the concrete surface to ensure that the concrete surface is smooth and smooth.

Paste carbon fiber cloth

Apply a layer of epoxy resin on the surface of the concrete, stick the carbon fiber cloth on the surface of the concrete, and then apply a layer of resin on the carbon fiber cloth to ensure a firm adhesion.

Maintenance and surface coating

After the carbon fiber cloth is pasted, it should be cured under natural conditions for about 10 days to ensure the bonding effect. In order to further improve the effect of carbon fiber reinforcement, the surface is painted after the maintenance is completed, which has a reinforcing effect and further improves the reinforcement effect of the bridge.

Sum up

By using carbon fiber reinforcement technology to reinforce the reinforced concrete hollow slab of the bridge, it shows that after the reinforcement, the dynamic performance of the bridge is effectively improved, and the cracks of the bridge are effectively repaired.