Old industrial factory building retrofitting

Retrofitting by CFRP fabric and steel plate

Fiber reinforced polymer(FRP) fabric can enhance the bending and shearing ability of the component, improve the bearing capacity of the component, improve the ductility of the original component, increase the anti-seismic ability, improve the crack resistance of the component and prolong the service life of the component.

Project overview

The workshop was built in 1949 and has been put into operation for about 40 years, no major civil engineering transformation has been carried out. The structure type of the workshop is complex, with the independent foundation, the reinforced concrete column, the brick column, the reinforced concrete roof beam, the reinforced concrete roof, the steel roof frame, the reinforced concrete skysill, the reinforced concrete large house panel system.

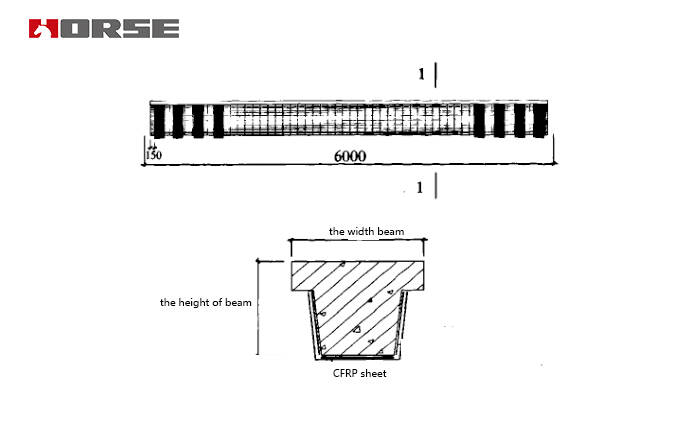

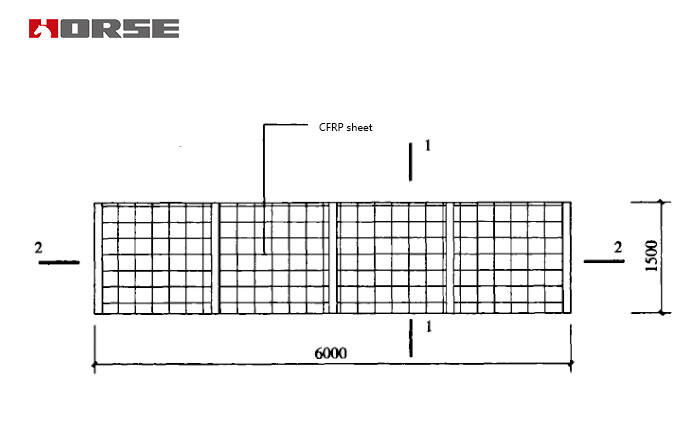

Reinforcement range and scheme

The building use time is long, the carbonization depth of the concrete component has basically reached the thickness of the concrete protective layer, and the fine cracks are produced, so the strength of the component is reduced.

Considering that the bearing capacity of members is not much reduced, and the construction conditions and engineering costs, and considering the durability of components, it is decided to use FRP fabric for strengthening. Because the carbon fiber fabric has good corrosion resistance, and the reinforcement method is simpler and faster.

Replacement of partially ribbed boards with partially damaged mushrooms. Because the carbonization depth of the large roof slab concrete of the two phase workshop has basically reached the reinforcement protection layer. If no protective measures are taken, the carbonization depth will continue to increase, resulting in corrosion of the steel bar and the failure of the whole component. At the same time, taking into account the large area of the roofs that need to be treated, the replacement time, the process are difficult and the capital investment is big, and combined with the test report and the actual situation, it is decided to use the stickup fiberglass cloth with more economical price to carry out the strengthening durability treatment. It can not only repair the contact between concrete cracks and isolated concrete surface, but also reinforce the slab.

The fiber reinforced polymer(FRP) composite strengthening system can enhance the bending and shearing ability of the component, improve the bearing capacity of the component, improve the ductility of the original component, increase the anti-seismic ability, improve the crack resistance of the component and prolong the service life of the component. At the same time, the construction technology is simple and easy does not affect the production, does not increase the section size and weight of the structure, which provides a good new way for the reconstruction of the old industrial buildings.