Panyu Lijiang garden bridge

crack repair and bonding steel plate

full bridge has a small area of a large number of concrete damage, exposed rebar disease, the damaged area is the sum of 13.46m2, single damaged area in the range of 0.01 ~ 0.65m2; such diseases have great influence on the durability of the structure, the damage location recommendations as soon as possible rust repair, ensure the durability of the structure meet the requirements

Project overview

Panyu Lijiang garden bridge across the three perfume Road, connecting the Luoxi Bridge and the Lijiang Garden residential area. The bridge was opened to traffic in May 1995. The bridge has 17 spans, which consists of 6 span continuous box girder with +3 span arch bridge of +8 span box girder is 525M, the total width of the main bridge deck 18m (1.50m+ 15m+ 1.50M Lane sidewalk pavement, bridge deck width (6m) of 4.50m+ 1.50M; the roadway pavement) design load of the bridge for loading car -20, Trailer -100 and population 3.5kN/m2. The bridge, board and column are No. 40 concrete, the sidewalk is No. 20 concrete, and the collision prevention column is No. 25 concrete.

Project disease

1.Substructure of bridge

According to the testing results, the bridge first ~ 6 span reinforced concrete continuous box girder structure, seventh ~ 9 span arch bridge structure, tenth to 17 span ordinary reinforced concrete box girder structure of the bridge; first ~ 6 and tenth ~ 17 across the span of the bridge, seventh to 9 for the main bridge superstructure of main span. Make the following diseases or defects.

1) bridge continuous box girder cracks are mainly distributed in the cross region positive moment, crack length in the range of 0.15 ~ 8.20m, width in the range of 0.08 ~ 0.24mm, a total of 10 crack width more than the "technical specification of maintenance for city bridge" (CJJ99-2003) the provisions of section 5.4 of the reinforced concrete member crack width limit the value of 0.20mm.

2) the main bridge (60m+90m+60m reinforced concrete arch bridge arch rib fracture) mainly distributed node location and cross connection in the vault position in the beam, and crack length in the range of 0.15 ~ 2.40M, width in the range of 0.08 ~ 0.30mm, the depth of the cracks in the reinforced layer within the scope of protection.

3) a total of 617 full bridge cracks, the crack length 454.61m, crack width in the range of 0.08~0.30mm, which is more than 100 0.15mm crack width, length is 80.75m; the crack width is greater than or equal to 0.20mm of the 36, a total length of 40.05m.

4) full bridge has a small area of a large number of concrete damage, exposed rebar disease, the damaged area is the sum of 13.46m2, single damaged area in the range of 0.01 ~ 0.65m2; such diseases have great influence on the durability of the structure, the damage location recommendations as soon as possible rust repair, ensure the durability of the structure meet the requirements.

5) a transverse crack appears on the ground at the position of the ninth span near the arch of the arch. The cause of this disease is the settlement of the soil by the river.

2.Bridge substructure

According to the field test results, the substructure of the bridge mainly has the following diseases or defects:

(1) 0# from the right side of the slope of the cone stone jointing crack, the slope of the cone sink, 4cm, weeds;

(2) there is a crack in the back of the platform and there is a trace of slurry.

(3) the beam pier damaged reinforcement, and multiple traces of water seepage;

(4) there are buildings under the bridge;

(5) the bearing has the diseases such as shear deformation, rubber layer cracking and aging.

3.Bridge deck system

According to the results of field testing, the main defects or defects of the bridge deck system are as follows:

(1) the bridge deck is paved with concrete, and the longitudinal and transverse cracks appear on the bridge surface, and the sigma L=104.75m;

(2) there are diseases such as concrete breakage, gluten, and so on in the deck of the bridge, and sigma A=15.79m2;

(3) 0# top bridge head lap unevenness, both sides high difference 0.6cm, causing a slight jump;

(4) there are cracks and sinks on both sides of the sidewalk board.

(5) there are many cracks on both sides of the guardrail and partial rust.

(6) the discharge hole is blocked and a small amount of water is accumulated on the bridge surface.

(7) aging of rubber belt in expansion joint, silt filling and car jumping phenomenon.

Reinforcement method

1.Reinforcement of bridge superstructure

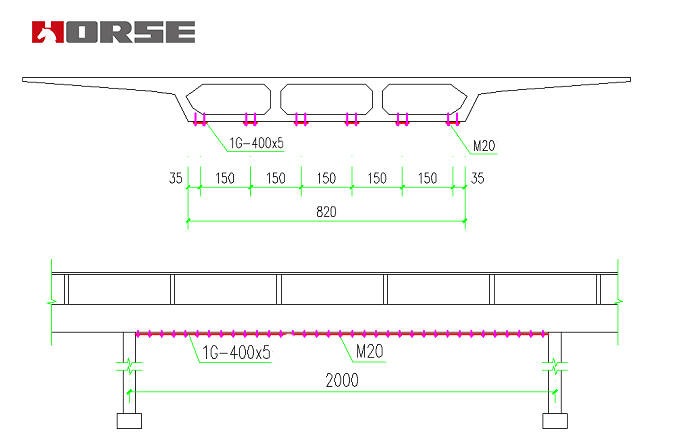

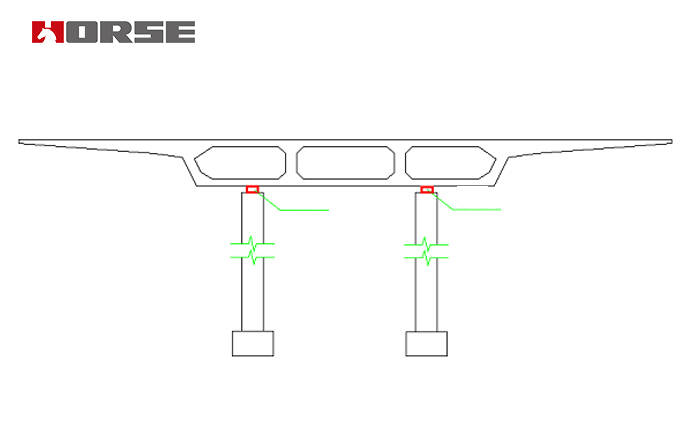

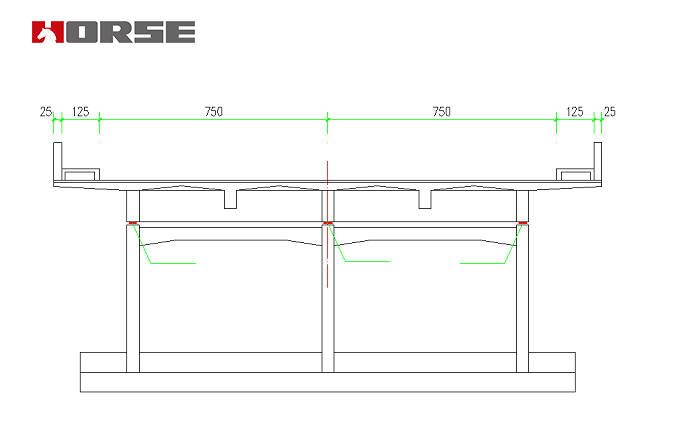

1)Reinforcement of continuous box girder with steel plate

1,2,5,6 span girder crack bridge was mainly distributed in the cross region positive moment in the bottom of the box, paste steel plate to improve the bearing capacity of bending longitudinal box girder concrete reinforcement method, as shown in Figure

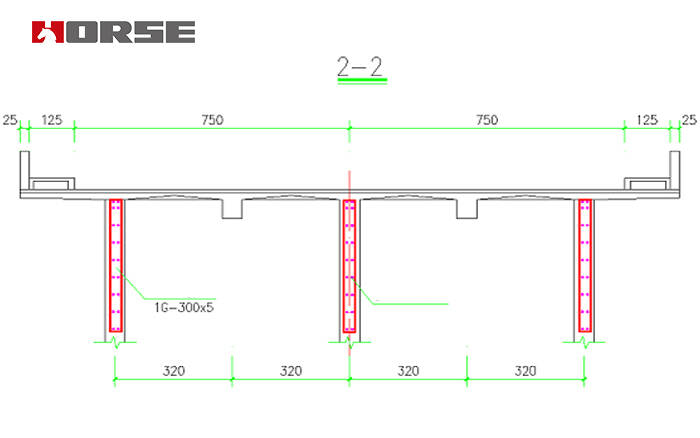

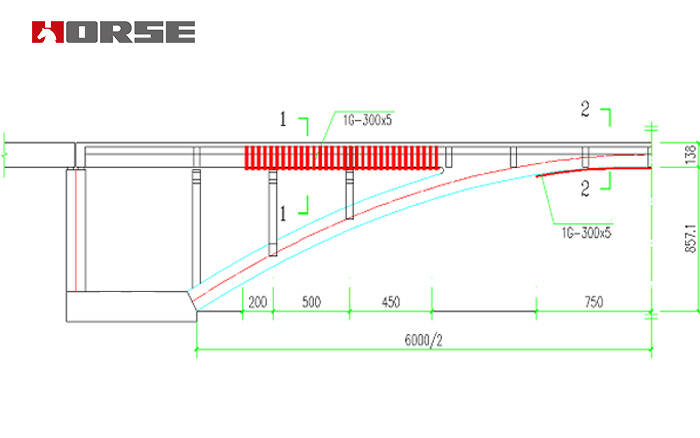

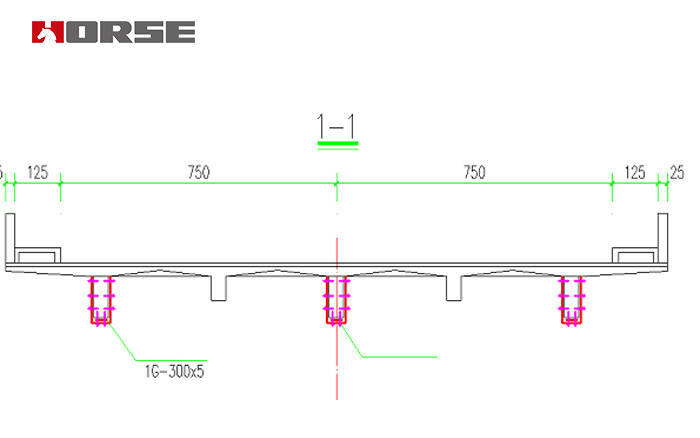

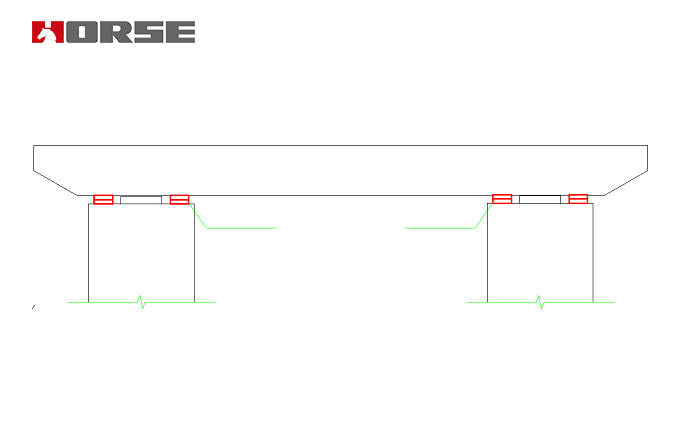

2) Main bridge pasting steel plate reinforcement

The main bridge (60m+90m+60m reinforced concrete arch bridge arch rib fracture) mainly distributed node location and cross connection in the vault position in the beam, beam, arch; in the cause of rib connected nodes location of cracks is mainly localized stress concentration, the main reason of cracks in the vault is affected by bending cracking. Therefore, the steel plate is attached to the bottom of the cracking part to improve the flexural capacity of the component.

3) crack treatment and concrete defect treatment

Crack treatment

The cracks in the superstructure of the bridge are treated as follows:

(1) for crack width is larger than 0.15mm, the pressure casting method;

(2) the surface sealing method is used to crack the crack width <0.15mm.

Treatment of concrete defects

(1) for the surface defects of concrete, after exposing the loose concrete, the exposed steel bars are derudied, and then repaired with polymer cement mortar after brushing the rust inhibitor.

(2) for the cavity and bellows exposed diseases, we should first remove the loose concrete, clean the concrete interface and dry it, then repair it with polymer concrete. When mending, it should be smeared by layer by layer, and the grouting hole is reserved at the hole in the upper side of the bellows. After the completion of the repair, the grouting holes in the upper side of the bellows are pressed through the reserved grouting holes, and the epoxy based cement slurry is used in the grouting material.

2.Substructure reinforcement

1) replacement support

1# Pier 1, 2# column support, Ninth span 1# arch rib 4# column support, Ninth span 2# arch rib 2# and 4# column bearing have shear deformation, rubber layer cracking and aging and other diseases. Replacement of the original bearing should be replaced.

2) new support

2# pier support, seventh span 6# pier support, sixth span 6# pier support, these pier columns are large in size, the spacing between pier column and beam is very small, and the bearing is deeply embedded, so it is difficult to replace the original bearing, so two supports are added to the original support.

3) crack treatment

The cracks in the substructure of the bridge are treated as follows:

(1) for crack width is larger than 0.15mm, the pressure casting method;

(2) the surface sealing method is used to crack the crack width <0.15mm.

the B3# axle abutment hat beam has obvious diagonal cracks. First, we should remove the concrete at the junction between the abutment hat beam and the approach box girder, and clean up the concrete in the cracks. After the high pressure water is washed, we use the structural glue to repair the cracks.

3. Bridge deck system

1) cleaning up the bridge surface, dredging the water pipe of the bridge surface, removing the rain from the pavement in time, and replacing the damaged person in the form of the original structure.

2) cleaning up the debris and weeds in the pier.

3) replacement of bridge expansion joint.

4) on the pavement damage suggestion: chisel the loose concrete on the broken surface of the sidewalk and fill in the concrete

Compound, vibrate and leveling and leveling, sprayed curing agent to keep health, and open traffic after the concrete reaches the strength of traffic.

5) widen the pavement cracks and the damaged parts of the concrete, clean up, inject the material of the seams, and open the traffic after the solidification is completed.

6) the small cracks in the railings are directly closed.

7) redo the 0# abutment pedal to make the top bridgehead smooth.