Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The cracks are first treated by grouting and sealing, so as to restore the integrity of cracked masonry, and then reinforce the treatment with carbon fiber fabric. After strengthening, it has been used for more than a year, and no new cracks have been found

Project overview

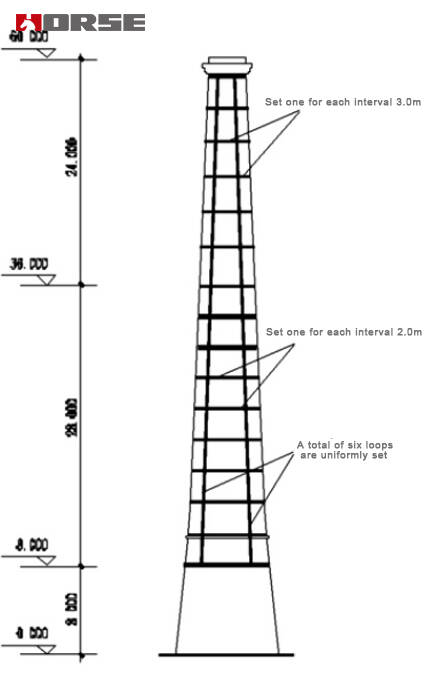

The large brick chimney of 20t/h boiler of a company was built in 1990, with a height of 60m. The whole chimney structure is divided into the foundation part, the 10m high concrete base part and the 50m high brick tube part. The foundation is an independent concrete foundation, with an outer diameter of 8.2m, a high 3.0m, and a C15 concrete foundation with a height of about 6m of the rubble concrete cushion. The bottom part of the shell is a cast-in-place reinforced concrete structure with a wall thickness of 300mm; the upper part of the brick tube is 2.5% in the outer edge, and two in the inner lining and the outer wall. The outer wall is MU10 brick and M7.5 mixed mortar section masonry. The thickness of each section is 10m to 30m section 90mm, 30m to 50m section 370mm, 50m to 60m section 240mm. The reinforcement is added in the horizontal ash seam of masonry. The steel bar is encrypted within the range of each section of each section, and the distance is two leather bricks. The lining is MU7.5 brick, 1: 1: 4 mixed mortar masonry, the thickness is 120mm.

Crack detection and cause analysis

The chimney body is seriously cracked, and the cracks are mainly vertical cracks, totally two. In the south of the barrel, it develops vertically up to 12m at the height of 20m. The width of the crack at the beginning is about 12mm. The width is on the right side of the climbing platform on the right side of the middle of the barrel, and the width is about 16mm. The crack is terminated about 4m above the rest platform of the climbing ladder. The other one is on the northwest side of the cylinder, the crack starts at 15m, the length is about 3M, and the maximum crack width is about 9mm. The two cracks extend into the interior of the masonry, and the bricks break.

After investigation and analysis, cracks are not formed in a short time, and are likely to develop at a certain speed. The main causes of cracks in the chimney are:

Influence of temperature change

Damage effect caused by the lining damage of the chimney

Effect of flue gas corrosion

Reinforcement scheme

Considering the crack length of the chimney for 20m, the cracks of the chimney masonry structure are treated with epoxy mortar seams first, and then the 250mm wide carbon fiber fabric is attached vertically along the concrete base of the top to the bottom (high 8m), and a total of 6 longitudinal carbon fiber sheets are separated according to the ring direction. From the lower part of the crack and elevation 12M, a 250mm wide ring of carbon fiber cloth is pasted up every 2.0m (center distance), sticking to the top of the chimney.

Matters needing attention

1) the brick masonry pasting carbon fiber cloth is different from the concrete base material. The mortar in the ash seam should be taken out and cleaned with compressed air and acetone, and then the ash seams are filled with the mending mortar. After the mortar is solidified, the carbon fiber cloth can be constructed.

2) the use of carbon fiber cloth should avoid bending, and it is forbidden to damage the carbon fiber cloth.

3) considering the stripping failure and actual reinforcement effect of the surface of the carbon fiber cloth and the reinforced components and the actual reinforcement effect, the number of bonding layers of the carbon fiber cloth on the same section should not exceed 3 layers, and the lap length of the carbon fiber cloth along the fiber direction should not be less than 200mm.

4) the raw materials of the resin should be sealed and stored away from the water source to avoid direct sunlight exposure.

5) then the glue is distributed, it should be deployed on site, and should be ventilated away from the fire source.

6) on-site construction personnel should take corresponding labor protection measures according to the use of resin materials.

Effect analysis

In this project, the cracks are first treated by grouting and sealing, so as to restore the integrity of cracked masonry, and then reinforce the treatment with carbon fiber cloth. After strengthening, it has been used for more than a year, and no new cracks have been found, and the control of cracks has been satisfactory. It shows that the carbon fiber reinforcement method is feasible.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good thixotropy carbon fiber leveling adhesive for concrete surface repairing

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening