Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How Do Different Substrates Differ In Their Compatibility With Carbon Fiber Strengthening?

The core differences in the compatibility requirements of different substrates for carbon fiber reinforcement systems stem from the substrate's own mechanical properties (strength, elastic modulus), surface characteristics (flatness, porosity) and environmental stability, requiring targeted adjustments to the bonding material parameters and interface treatment solutions.

1. Concrete Substrate:

Key Focus: Interface Bonding and Substrate Strength Matching

Concrete substrates have moderate strength and a porous surface. The key to reinforcement compatibility is ensuring effective bonding between the carbon fiber and the substrate, avoiding bond failure due to insufficient substrate strength or improper interface preparation.

The base material strength must meet the standard: the concrete cube compressive strength standard value must be no less than C15. Otherwise, interface strengthening treatment (such as applying an interface agent or spraying high-strength mortar) is required.

The interface must be "rough and clean": Surface laitance and oil stains must be removed, and a uniform roughness (roughness controlled within 4-8μm) must be achieved to ensure that the impregnating adhesive can penetrate the pores and form a mechanical bond.

2. Steel Structural Substrate:

Key Focus: Corrosion Protection and Thermal Expansion Compatibility

Steel structural substrates are high-strength, smooth, and susceptible to corrosion. The key to reinforcing compatibility lies in addressing the bonding between the anti-corrosion coating and the impregnating adhesive, as well as the thermal expansion difference between steel and carbon fiber.

The surface must be "rust-free and free of coating interference": All rust on the steel structure surface must be thoroughly removed (to Sa2.5 or St3 rust removal standards). If the existing anti-corrosion coating (such as paint or galvanizing) is incompatible with the impregnating adhesive, it must be partially removed to the bare steel surface.

Controlling the effects of thermal expansion differences: The thermal expansion coefficient of steel (12×10⁻⁶/°C) is higher than that of carbon fiber (1.5×10⁻⁶/°C). Large temperature differences can easily generate interfacial shear stresses, necessitating design-controlled reinforcement lengths or the addition of elastic transition layers.

3. Masonry Substrate:

Focus on Substrate Integrity and Interface Reinforcement

Masonry substrates (bricks and blocks) have low strength, poor integrity, and low surface flatness. The key to strengthening compatibility is to first repair substrate defects and then improve bonding reliability through interface treatment.

The substrate needs to be repaired and then reinforced: If the masonry has cracks (wider than 0.3mm), voids, or loose blocks, it should first be filled and repaired with cement-based repair mortar or epoxy mortar to ensure that the substrate can transmit the load.

The interface needs to be "reinforced and smoothed": If the masonry surface has large pores and poor flatness, a mesh (such as alkali-resistant fiberglass mesh) should be applied first, followed by a coating of interface mortar to create a smooth transition layer. This prevents localized hollowing caused by uneven substrates when the carbon fiber cloth is directly adhered.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

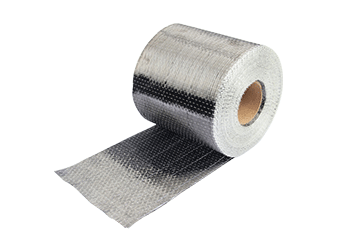

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength unidirectional carbon fiber fabric for concrete repair and structural strengthening

High strength unidirectional carbon fiber fabric for concrete repair and structural strengthening