Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Based in Shanghai

Horse Construction: A Professional Force in China's Injection Anchoring Adhesive Industry

In the field of structural reinforcement and retrofitting, the reliability of anchoring systems directly impacts project safety and durability. As a professional manufacturer of injectable adhesive anchors in China, Horse Construction delivers efficient and secure structural anchoring solutions to global clients through its core product HM-500 injectable adhesive anchor, leveraging superior quality, advanced technology, and comprehensive services to enhance the stability and performance of various construction projects.

Deepening Technology: Building High-Performance Anchoring Core Products

Horse Construction consistently upholds technological innovation as its foundation. Its star product, the HM-500 Injection Anchoring Adhesive, is a two-component modified epoxy resin adhesive specifically developed for demanding engineering environments. From formulation design to production processes, every stage undergoes rigorous control to ensure the product meets industry-high standards in performance.

From the basic parameters, the HM-500 features precise product specifications: a 390ml capacity design suitable for most engineering usage requirements, a 3:1 mixing ratio for easy operation and control, and a highly visible red appearance for monitoring colloidal distribution during construction; the density of 1.5±0.1g/cm³ ensures the colloidal material fills anchor holes densely, laying the foundation for subsequent anchoring strength.

In terms of core performance indicators, the HM-500 demonstrates professional-grade standards: the post-mix viscosity remains stable at 18-22Pa・S, ensuring both fluidity and controllable construction; its mechanical properties are particularly outstanding, with splitting tensile strength ≥8.5MPa, flexural strength ≥50MPa, and compressive strength ≥60MPa. Even under conditions involving C30 concrete substrate, φ25 steel reinforcement, and an anchorage length of 150mm, the tensile strength still reaches ≥11MPa, while the bond strength at 125mm anchorage length is ≥17MPa, fully meeting the strength requirements for structural connections. Additionally, a thixotropic index of ≥4.0 ensures the colloidal does not flow in vertical or inclined holes, while a heat deformation temperature of ≥65℃ accommodates high-temperature environments. The steel-steel T-impact peel length ≤25mm reflects superior toughness, preventing anchorage failure due to impact.

Multi Dimensional Advantages: Solving The Core Pain Points Of Engineering Anchoring

Compared to traditional anchoring materials, HM-500 injectable anchoring adhesive has become a reliable choice in construction engineering due to its unique advantages.

One of its core guarantees is a 100% pass rate for tensile testing. Whether it is random sampling testing on construction sites or laboratory standard condition testing, HM-500 can stably pass the pull-out test, eliminating safety hazards caused by material performance fluctuations and providing a basis for engineering quality.

The special formula design achieves the effect of structural integration. Colloids can form strong chemical bonds with concrete substrates and steel bars, rather than simple mechanical interlocking, making them a complete force bearing whole, greatly improving the fatigue resistance and long-term stability of the anchoring system, and reducing maintenance costs in the later stage.

Strong extensibility and environmental adaptability break the limitations of construction scenarios. The elastic reactive groups in the molecular structure of epoxy resin enable colloids to have both high strength and good toughness, and can cope with stress caused by slight structural deformation; Even in smooth anchoring hole walls, damp substrates, or high temperature weather, HM-500 can still maintain excellent bonding performance and construction operability, without the need for additional substrate treatment to ensure anchoring effect and improve construction efficiency.

In addition, the product also has the characteristics of safety and non toxicity, which meets the requirements of modern architecture for environmental protection and the health of construction personnel; The two-component plastic hard tube packaging is convenient for storage and transportation, and can be mixed and injected with a dedicated glue gun. It is easy to operate and reduces the construction threshold.

Widely Applicable: Covering Structural Requirements In Multiple Fields

With excellent performance and advantages, HM-500 injection type anchoring adhesive has been widely used in various construction engineering scenarios, becoming a "reliable link" for structural connection and reinforcement.

In the anchoring connection of structural steel bars, whether it is the extension and splicing of walls, floors, stairs, columns, foundations, or the connection of new and old building structures, HM-500 can achieve a firm connection between steel bars and concrete, ensuring effective force transmission. For example, in residential and factory expansion projects, this product can quickly complete the steel bar anchoring of new components and the original structure, shorten the construction period, and not damage the integrity of the original structure.

HM-500 also plays an important role in the field of building and bridge renovation and reinforcement. For the performance degradation of concrete components in old buildings, reinforcement and repair of bridge support connection parts, or reinforcement of structural nodes affected by vibration in industrial plants, this product can accurately embed anchor holes to provide additional support for components, restore and improve structural bearing capacity, and extend the service life of buildings.

In terms of steel structure anchoring, the connection between steel columns, steel beams and concrete foundations is a key node. HM-500 can firmly fix the steel structure and concrete substrate through anchor bolts or direct bonding. Its steel steel tensile shear strength is ≥ 16MPa, which can effectively resist the shear force of the steel structure under load. It is suitable for large venues, industrial parks and other steel intensive building projects.

Professional Services: Comprehensive Support from Products to Solutions

As a professional manufacturer in the field of injectable anchoring adhesive in China, Horse Construction not only provides high-quality products, but also is committed to providing customers with full process service support to make project implementation more efficient.

We provide our customers with a comprehensive technical information system: you can download the Technical Data Sheet (TDS) of HM-500 injection type anchoring adhesive at any time to obtain detailed performance parameters, construction processes, and precautions; At the same time, provide product application videos to visually demonstrate the construction process of anchoring steel bars, helping the construction team quickly grasp the key points of operation; In addition, a professional anchoring system manual can provide reference for engineering design, assisting engineers in selecting suitable anchoring schemes based on specific working conditions.

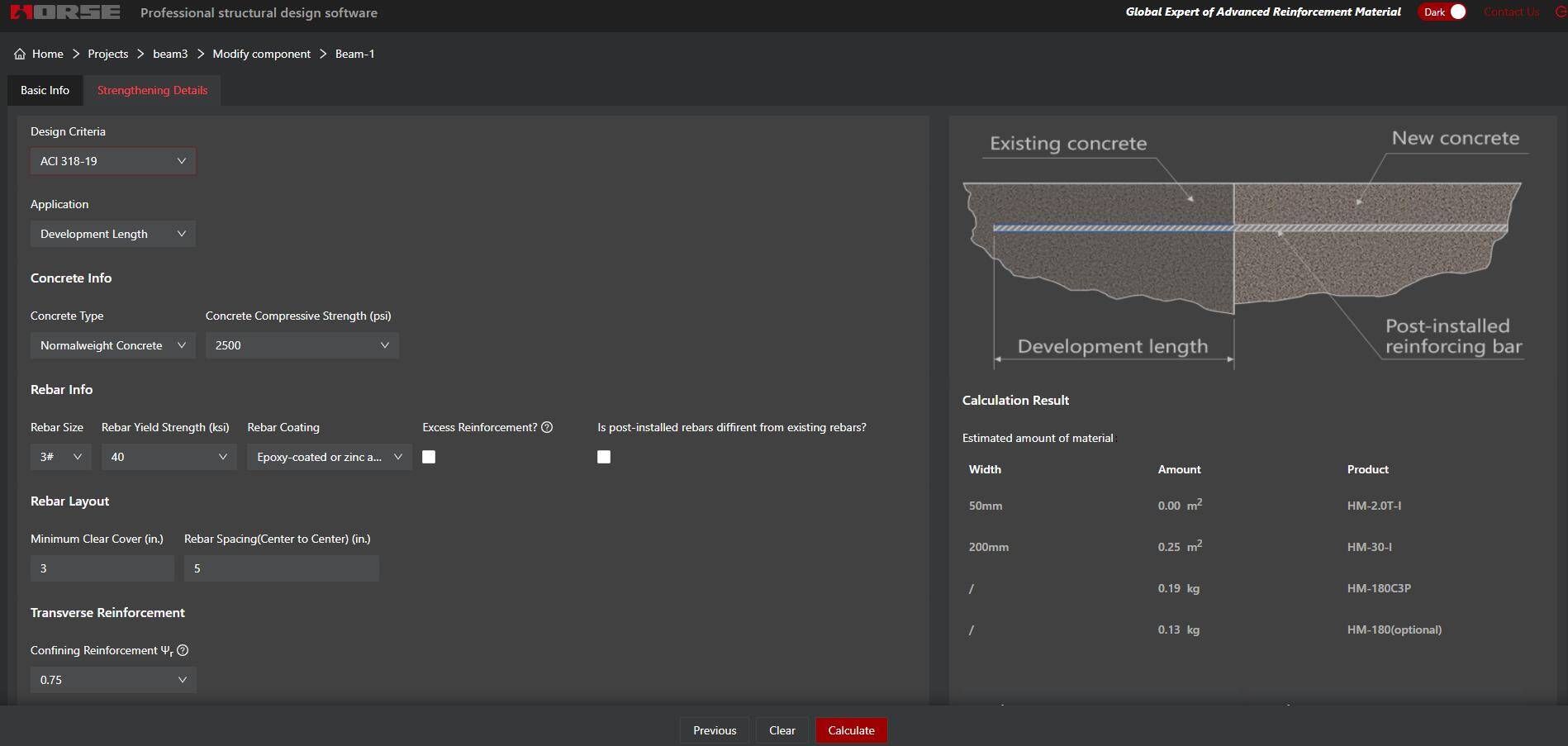

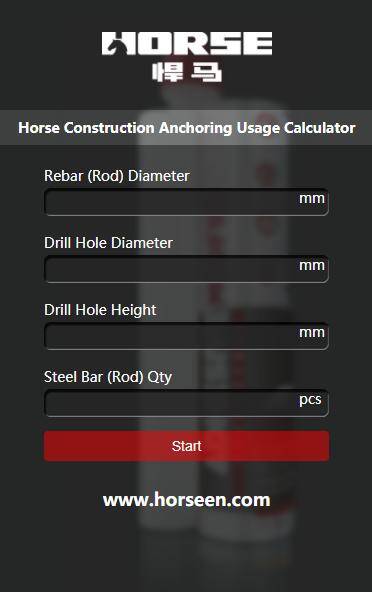

We have developed a patented anchor glue calculator to address common usage calculation challenges in engineering. Customers only need to input parameters such as anchor hole diameter, depth, and quantity to quickly and accurately calculate the required usage of HM-500, avoiding material waste or delays caused by insufficient usage, and providing strong support for project cost control.

In terms of construction guidance, we have simplified the operation process of HM-500, which can complete anchoring construction through six steps of "drilling cleaning brushing glue planting curing" without the need for complex equipment; At the same time, the professional technical team can respond to customer inquiries at any time, provide customized construction suggestions for special working conditions, and ensure that every anchoring node meets the design requirements.

Quality Commitment: Based In China, Serving The World

Since its establishment, Horse Construction has always been committed to the mission of "manufacturing the highest quality reinforcement materials, eliminating safety hazards in concrete structures, saving lives and buildings". From raw material procurement to production and processing, a strict quality control system has been established: high-purity epoxy resin and high-quality curing agents are selected to ensure the stability of raw materials; Real time monitoring of colloid viscosity, curing speed and other indicators during the production process to prevent unqualified products from leaving the factory; Each batch of products retains samples for easy traceability, earning the trust of global customers with the rigorous quality of Chinese intelligent manufacturing.

Nowadays, Horse Construction's HM-500 injection type anchoring adhesive has been widely used in construction projects in China and multiple countries and regions overseas. From civil buildings to industrial facilities, from bridge engineering to special structures, we always provide professional and efficient services to solve anchoring problems for customers and help ensure smooth project delivery.

Choosing Horse Construction and HM-500 injection type anchoring adhesive means choosing a guarantee of structural safety and a commitment to engineering quality. We look forward to working together with global partners to build a more stable and durable future of architecture through innovative technology and high-quality products!

(For more product information or technical support, please contact us.)

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

High-strength anchor bolt with vinyl resin as main materials, composed of selected quartz sands, curing agents and glass tubes

Two-component modified epoxy resin adhesive, applied to chemical planting reinforcing bar and anchor bolt anchoring