Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How To Apply Carbon Fiber To Different Parts of Bridge? For Example, Girder, Bridge Pier, Node

Regardless of which part of the bridge, pasting carbon fiber cloth follows a core principle: to align the fiber direction of the carbon fiber cloth with the main force direction of that part, in order to leverage its high-strength advantage.

1. Reinforcement of girder

The main girder is the core component that bears bending moment and shear force.

Reinforcement objective: To enhance the flexural and shear bearing capacity.

Paste method:

Enhance bending resistance (most commonly):

Location: Paste on the bottom surface of the tension zone of the girder.

Direction: The fiber direction is consistent with the axis direction of the girder (longitudinal).

Key point: If space permits, bend and stick a certain height upwards on both sides of the beam bottom edge to form a "U" - shaped hoop, taking into account some shear resistance.

Enhance shear resistance:

Location: Paste on both sides of the web slab of the girder.

Direction: The fiber direction is perpendicular (transverse) to the beam axis, forming a closed annular hoop.

Key point: The spacing between hoops is determined by calculation, and the denser the hoop, the better the shear resistance effect. Usually used in conjunction with longitudinal U-shaped clamps.

2. Reinforcement of bridge piers

Bridge piers mainly bear axial pressure, bending moment, and shear force, which are the key to earthquake resistance.

Reinforcement objective: Improve shear bearing capacity, ductility (seismic performance), and crack resistance.

Paste method:

Core method: Circular wrapping.

Direction: The fiber direction horizontally surrounds the bridge pier.

main points:

A closed loop must be formed without any breakpoints. For rectangular piers, the edges and corners should be polished into arcs to prevent stress concentration.

For bridge piers that bear significant horizontal forces, a structure similar to a steel mesh can be formed by first attaching hoop hoops and then attaching longitudinal strips to the hoop hoops, with the hoop hoop as the main support and the longitudinal support.

3. Reinforcement of nodes (such as the connection between the cover beam and the column)

Nodes are the intersection points of forces, with complex and crucial forces.

Reinforcement objective: To enhance the shear resistance and integrity of the core area of the node.

Paste method:

Core method: U-shaped hoop+longitudinal pressure strip.

Steps:

Paste horizontal U-shaped hoops around the node area on both sides and bottom of the cover beam.

Then, at the opening of the U-shaped hoop (i.e. the top of the cover beam), a longitudinal pressure strip is pasted to "seal" the U-shaped hoop and form a three-dimensional constraint system.

Key point: This method can effectively constrain the concrete in the core area of the node, preventing it from being crushed under complex stress.

4. Reinforcement of prestressed anchorage zone

The anchorage area is a highly concentrated area of local stress, which is prone to splitting cracks.

Reinforcement objective: To resist the enormous local pressure under the anchor and prevent concrete cracking.

Paste method:

Core method: Partial circular wrapping.

Direction: Stick horizontal circular hoops around the anchor pad, with the anchor as the center.

main points:

The width and number of layers of the hoop need to be accurately calculated.

It is necessary to ensure that the concrete surface in the bonding area is flat and clean to ensure the bonding effect.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

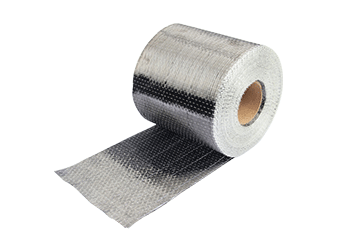

High strength unidirectional carbon fiber fabric for concrete repair and structural strengthening