Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The development of concrete crack repair technology provides more reliable and efficient solutions for building maintenance and structural reinforcement.

06

Sealing treatment

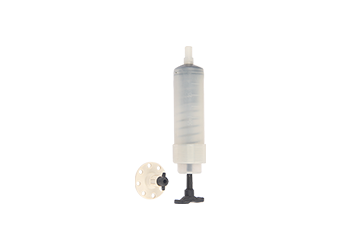

Seal the glue injection port, consistent with the sealing surface.

After grouting, if there is no water pressure or other pressure inside the joint, the grouting nozzle can be removed and the sealing layer can be removed after the initial setting of the grout. Conversely, only when the grout reaches its strength can it be removed and cleaned.

After removing the syringe, clean the glue injection hole and use structural glue to fill and level the hole

07

Quality inspection

Quality inspection is the assessment of whether the construction quality meets the requirements of relevant acceptance standards.

Quality inspection

The physical and mechanical performance indicators of the grouting material and sealing adhesive must comply with the provisions of the construction and acceptance specifications, and the technical performance indicators of the product's factory certificate, test data, and on-site sampling tests must be checked.

The alignment of the grouting nozzle must be accurate when riding the seam, and there should be no dust or other debris blocking the riding seam opening; The grouting holes reserved for grouting must be grouted.

Effect detection

After gluing, the visual effect can be tested by introducing pressure water or compressed air. Inject pressure water, measure water absorption rate, compare the anti-seepage effect before and after grouting, there should be no leakage on the joint, and there should be no leakage in the cracks that leak before grouting. When air is introduced, the changes in breathability before and after can be compared.

The actual effect after glue injection should be tested using ultrasonic or core drilling sampling when the glue curing time reaches 7 days. The ultrasonic method is used to determine the density of grouting by measuring the changes in sound wave velocity before and after grouting; Riding and diagonal drilling cores can be used to check the fullness of crack filling, and complete core samples can be used for bonding tensile strength testing to test the bonding effect.

If there is a requirement for reinforcement while pouring glue, a core should also be taken for splitting tensile strength testing. The holes left after the core is taken should be filled tightly with structural glue mixed with quartz sand.

08

Precautions

Details determine success or failure.

The concrete surface with many honeycomb and pitted surfaces on both sides of the joint is not cleaned and sealed properly, making it prone to leakage during grouting.

During the preparation of the slurry, uneven stirring resulted in uneven solidification of the adhesive inside the seam.

The two components of sealant A and B have a relatively large proportion, resulting in a small amount of one-time mixing and inaccurate weighing; When preparing, a measuring cylinder can be used to prepare according to the volume ratio; Excessive diluent during viscosity adjustment results in the slurry not reaching the predetermined strength after solidification.

The hole of the glue nozzle is not properly blocked, and before the initial setting of the slurry, it leaks and voids appear in the joint body. The bolts used for blocking during construction should be wrapped with raw tape and then tightened.

The judgment of moisture and dryness on the internal base surface is incorrect, and the injection sealant is used incorrectly, or there is too much dirt that affects the bonding of the base surface that has not been cleaned, resulting in weak bonding of the base surface and affecting the bonding effect.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack