Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Bonded Steel Reinforcement On Concrete Frame Structures

Bonded steel reinforcement can enhance the overall bearing capacity and deformation resistance of the building structure. This method is currently the most common and a relatively mature reinforcement method, and there are corresponding normative constraints in the industry. Through the reinforcement method of bonding steel, the load performance of each concrete member can be greatly improved quickly, and at the same time, it takes up less space and conforms to the national standard, which is unmatched by the previous reinforcement methods.

The food processing plant has been put into operation for 5 years, and it is necessary to improve the production process, replace a new set of production equipment, and at the same time strengthen the factory building.

In order to reduce the construction period and reduce the project cost at the same time, the whole implementation process selects the reinforcement and reinforcement scheme of sticky steel. The highest level that all sections of the frame main beam can carry is regarded as the certificate for planning the reinforcement plan.

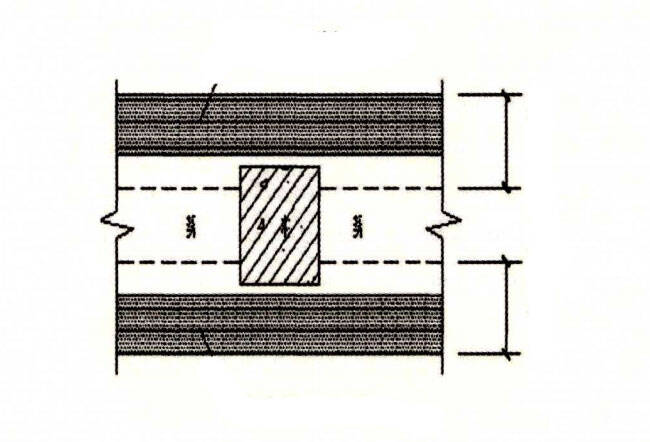

The reinforcement measures in the tension area of the front section of the mid-span flexural member can be achieved by adhering the steel plate to the outer layer of the tension area. In order to make the project implementation and operation process more convenient, the reinforcement measure of the normal section bearing capacity of the negative bending moment area of the frame main beam on both sides of the center column is to adhere the steel plate to the plate surfaces on both sides of the beam, and the range of the paste is 4 times the plate thickness. The cross-sectional view of the board with the steel plate attached is shown in the figure.

In the construction process, the steel plate concrete needs to be firmly adhered, which requires the adhesive surface to be flat and clean, and it is necessary to use a brush with a hard texture and a strong detergent to wipe the surface of the adhesive surface. This will remove oil from the outside of the adhesive surface, then rinse the exterior with cold water.

Then, the surface of the adhesive surface is polished smooth, and the rough outer side with a thickness of 2-3mm is polished off until the adhesive surface shows a new interface. Dust and particles from sanding are then removed with oil-free compressed air. If the adhesive surface of the concrete is relatively new and less oily, there is no need to use a detergent, and the adhesive surface is directly polished, and the rough outer surface with a thickness of 1-2mm is polished off until the adhesive surface shows a new interface. Then, the dust and particles generated by grinding are removed by rinsing with oil-free compressed air or water, and finally the surface is wiped clean with acetone. At the same time, the adhesive surface of the steel plate should be derusted and roughened to improve its adhesion. If the steel plate has no signs of rust, or is slightly rusted, you can directly use sandblasting, emery cloth or flat grinding wheel to grind the surface of the steel plate until the surface shows metallic brightness. The greater the roughness of grinding, the better. The grinding pattern should be perpendicular to the direction of force on the steel plate. Finally, wipe clean with absorbent cotton dipped in acetone. If the surface of the steel plate has a large degree of rust, a certain concentration of hydrochloric acid should be selected and soaked on the surface of the steel plate for 20 minutes to completely remove the generated rust. Then, the treated surface is rinsed with lime water to neutralize excess acid ions, and finally a flat grinding wheel is used for grinding to process the texture.

The construction operation process of the reinforcement project used in the workshop is: treatment of the surface of the bonded concrete and steel plate, preparation of the adhesive, unloading of the reinforcement member, coating, paste, fixing and pressing, curing, unloading, support, inspection, anti-corrosion and painting.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High-strength anchor bolt with vinyl resin as main materials, composed of selected quartz sands, curing agents and glass tubes

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement