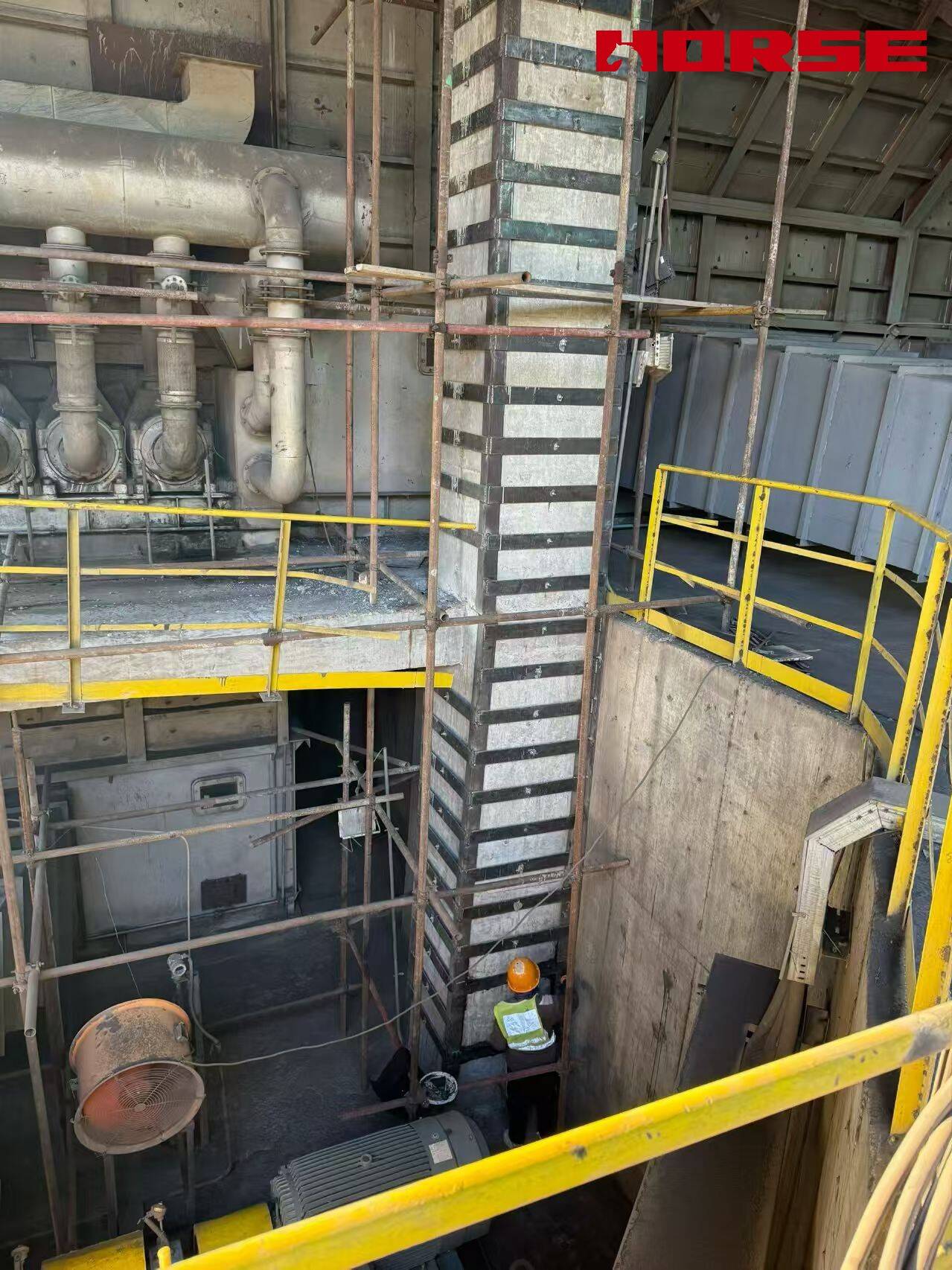

Reinforcing Cement Plant Columns

Steel Jacketing Adhesive

Due to the long-term production operation of the cement plant, some concrete columns have problems such as insufficient bearing capacity and surface damage, which affects production safety and structural stability. The columns need to be reinforced and transformed to restore and improve the structural bearing capacity and ensure the normal operation of the production line.

1. Project Overview

Due to the long-term production operation of the cement plant, some concrete columns have problems such as insufficient bearing capacity and surface damage, which affects production safety and structural stability. The columns need to be reinforced and transformed to restore and improve the structural bearing capacity and ensure the normal operation of the production line.

2. Reinforcement plan

The steel jacketing reinforcement method is used to reinforce the problematic column as a whole:

Clean the damage, oil stains and debris on the surface of the column, and repair and level the cracks and defective parts;

Process the shaped steel according to the designed size, install the shaped steel on the surface of the column, and form an overall frame through welding and bolting;

HM-120M structural adhesive is poured into the gap between the section steel and the column to ensure that the section steel and concrete are closely combined and jointly bear stress;

Anti-corrosion treatment is performed on the surface of the section steel to improve the durability of the reinforced structure.

3. Construction process

Preliminary preparation: Complete on-site survey, scheme design and on-site acceptance of materials (section steel, structural adhesive, anti-corrosion coating, etc.);

Column treatment: manually clean the column surface, repair damaged parts, and ensure that the reinforcement surface is flat and clean;

Section steel installation: Precisely position and fix the section steel, complete welding and bolt connection, and ensure the stability of the section steel frame;

Pouring and anti-corrosion: pour HM-120M structural glue into the gap between the section steel and the column. After the glue solidifies, apply anti-corrosion paint on the surface of the section steel;

Acceptance: After the construction is completed, it is confirmed that the reinforcement effect meets the design requirements through visual inspection, bearing capacity testing, etc.

4. After reinforcement

The bearing capacity of the column has been significantly improved to meet the production load requirements of the cement plant;

The structural stability is enhanced and the safety hazards of the original column are eliminated;

The reinforced structure has good durability and can adapt to the harsh production environment of cement plants and extend the service life of the building.