Bridge Maintenance Engineering

Prestressed Carbon Fiber Plates

Select language

Prestressed Carbon Fiber Plates

The prestressed carbon fiber plates is used to reinforce the bridge as a whole to enhance the stability and durability of the bridge structure.

Project

A bridge project has a total length of 586m and a width of 28m. It is a double-width bridge and is designed according to two-way four-lane. The upper structure of the bridge adopts prefabricated prestressed T beams, the bridge deck pavement is cast-in-place concrete, the roadway is 2×10.25m, and the sidewalk is 2×1.9m. The substructure of the bridge is a pile foundation column pier, a U-shaped platform, and a plate rubber bearing. Because the bridge was built for a long time, after many years of use, the bridge structure has a lot of disease problems, such as cracks in the web, damage to the bearing, exposed ribs on the pier body, and damage to the bridge deck. In order to eliminate the disease and restore the performance of the bridge, it was decided to use prestressed carbon fiber plates to reinforce the bridge. The following focuses on the analysis of the application of carbon fiber panels in the bridge reinforcement construction.

Bridge Reinforcement Scheme

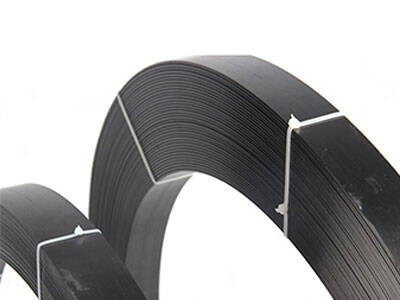

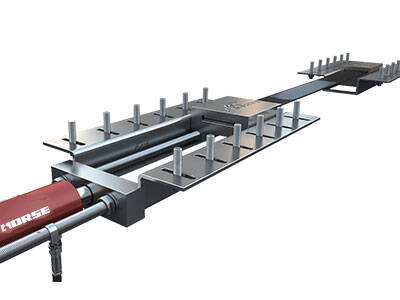

According to the on-site test results of the bridge bearing capacity, for the T beam, the beam body is reinforced by pasting prestressed carbon fiber plates on both sides, so as to enhance the bearing capacity of the T beam and improve its flexural performance. The carbon fiber boards were pasted on both sides of the beam body, the distance between the left and right ends of the board and the beam end was 200cm, the board width was 10cm, and the board thickness was 0.2cm. The prestressing is simultaneously tensioned on both sides of the beam body, and the method of graded tensioning is adopted. When all the carbon fiber panels of the beams are fully tensioned, use structural glue to fill the gaps between the panels and the beams, and finally fix them with compression strips.

Key points of construction technology

1. Measuring and positioning

2. Base cutting groove

3. Drill anchor holes

4. Remove the residue in the hole

5. Base surface treatment

6. Implant anchors

7. Install anchor base and carbon fiber board

8. Tension

9. Compression and protection

Website Map | Corporate | Contact | Privacy