Beam Reinforcement Reconstruction

Beam Reinforcement Reconstruction

Reinforcement can meet the requirements of use, and the existing strength data of its beams, slabs, columns and foundations are put forward, which provides a calculation basis for reinforcement and reconstruction.

The original main factory building is a concrete frame structure with a plane dimension of 36m in length, 16m in width and 24.9m in height. Due to the requirements of the process, in addition to the reinforcement of the original beams and slabs, it is necessary to increase the height of two floors, that is, the height of the workshop after the renovation and reinforcement reaches 35.4m. Therefore, it is necessary to carry out reinforcement and renovation design for the main workshop structure.

After the inspection of the engineering structure, according to the data provided by the on-site inspection and appraisal, it is determined that the reinforcement can meet the requirements of use, and the existing strength data of its beams, slabs, columns and foundations are put forward, which provides a calculation basis for reinforcement and reconstruction.

Pillar reinforcement

Column reinforcement is divided into two situations. If the calculated reinforcement is not satisfied, the angle steel and steel plate hoop are reliably integrated with the concrete column through bolts and epoxy resin by using the external bonding angle steel method, and the external mortar is used for anti-corrosion. If the calculated axial compression ratio is not satisfied, the method of increasing the section is adopted, and the reinforcement is connected with the original structure to enhance the integrity.

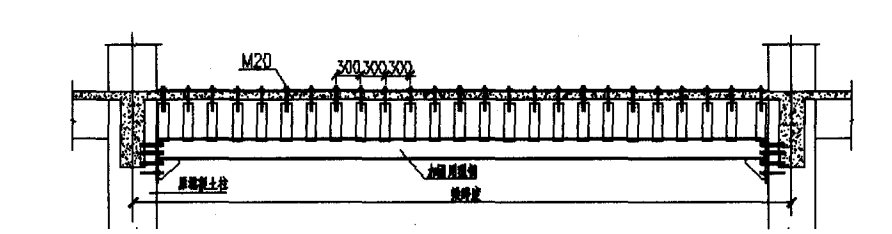

Beam reinforcement

The beam reinforcement of the project adopts the steel reinforcement method, which has the advantages of reducing the curing time of the concrete and shortening the construction period. As for the lower part of the original structural beam, the profiled steel beam is connected to the original concrete beam through steel plates and bolts.

The construction period is 3 months, and it was completed and put into production in 2014. The use effect is good, it meets the requirements of the new process, improves the recovery rate of clean coal, reduces pollution, and achieves good economic and social benefits.