Building Reinforcement

Bar Planting Reinforcement

Reinforcement Process Of A Building And Precautions For Bar Planting Reinforcement

Project Overview

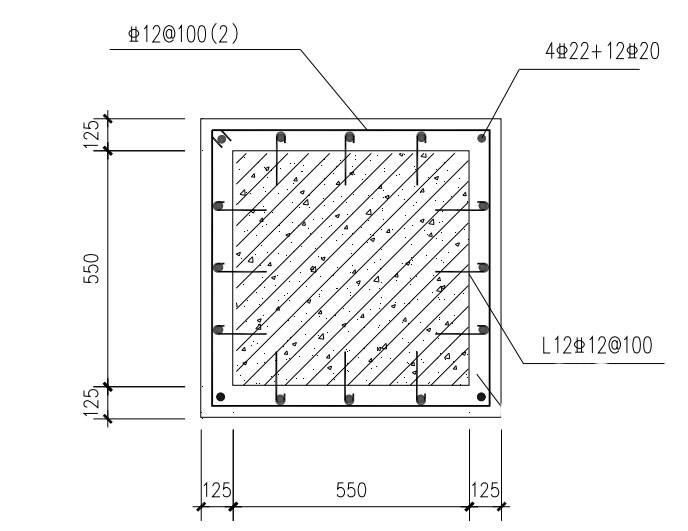

A commercial building on the east side of Dongfangzhimen, Xinggang Street, Industrial Park. The project overview is as follows: This project is a 3-storey reinforced concrete frame structure, with three floors above ground and one basement floor, with a height of 4.5m. The typical column net is 8.4m×8.4m, the typical column section of the basement is 550×550mm, and the typical column section above the basement roof is 500×500mm. The foundation form is a prestressed pipe pile foundation with a beam-slab waterstop. The project was designed and constructed in 2004 and completed and put into use in 2005. In 2014, because a subway tunnel needs to pass under the commercial building, the commercial building needs to be partially demolished in the subway tunnel passing area, and the remaining part is in accordance with the requirements of the owner and the current regulations. The large holes on some floors were closed with cast-in-place beams, and four stairs were added. The structural system, structural arrangement, and service loads of the remaining parts remain basically unchanged, and the design code versions adopted in the original design and the retrofit design are basically the same.

The main process of reinforcement and transformation

Before the existing buildings are reinforced and reconstructed, a testing company with special testing qualifications should conduct reliability appraisal of the original structure. When there are seismic requirements, the seismic capacity appraisal of the original structure shall be carried out according to the current national standards. These two appraisal reports should be used as the premise and basis for the reinforcement and reconstruction design of the project. According to the appraisal report and the calculation results of the overall modeling, the reinforcement scheme is selected, and then the reinforcement construction drawing design is carried out. Construction drawings must be reviewed and approved before they can be used for construction. Before the construction of structural reinforcement, the construction organization design shall be prepared according to the design requirements and structural characteristics. The construction shall be strictly controlled in accordance with the corresponding technical standards, and the quality inspection and project acceptance shall be carried out in accordance with the national standards.

Material requirements and construction technology of planting bars

Adding beams, slabs and columns and enlarging cross-section methods all require the use of bar-planting technology. When using bar-planting technology, one should be familiar with the relevant material requirements and construction techniques to ensure that the design and construction are economical, reasonable, safe and reliable.

(1) The selection of rebar-planting glue for load-bearing structures should strictly follow relevant regulations to ensure the durability, environmental protection and non-toxicity of the rebar-planting glue. Reinforcement glue should be packaged in hard cans. The shelf life of flexible packaging is short and it is easy to be damaged and deteriorated.

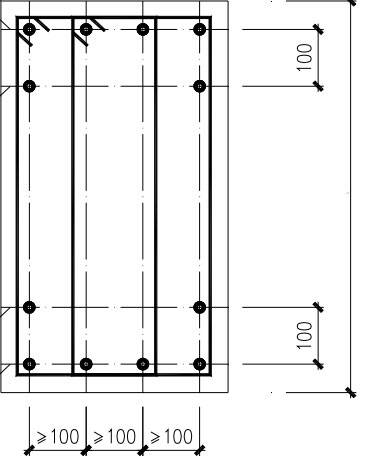

(2) When planting bars, the center distance of adjacent planting bars should not be less than 100mm, the protective layer of the planting bars in the original structure should not be less than 40mm, and the protective layer of the stirrups should meet the corresponding specification requirements. When the slabs and walls with a thickness of less than 150 are planted with double-row steel bars, the double-row steel bars shall be planted with plum-shaped dislocation.

(3) When planting reinforcement, the reinforcement should be welded first and then planted; if there is difficulty, the welding must be done later, and the distance between the welding point and the concrete surface of the base material should be greater than 15d, and the roots of the exposed part of the reinforcement should be wrapped with a water-impregnated wet towel.

(4) The minimum thickness of reinforced concrete components used for planting reinforcement should be greater than the depth of planting plus 2D (D is the diameter of the drilled hole).

(5) The concrete interface (bonding surface) at the junction of the old and new beams, slabs and columns should be chiseled. The method and requirements are detailed in Section 1.8 on page 8 of "Concrete Structure Reinforcement Structure" 13G311-1.

Reinforcement of the floor

Generally speaking, the elevation relationship between the floor slab and the floor beam is that the top of the slab and the top of the beam are flat. If the floor beams already exist, the new floor slabs can only plant the steel bars at the lower part, and cut the protective layer of the top of the floor beams about 100mm wide and 50mm high, and the steel bars on the slabs can be directly welded with the upper bars of the adjacent slabs.

Beam planting

In the preliminary stage of the reinforcement design of this project, after inspection, the reinforcement detailed drawing drawn by the reinforcement company shows that the net distance of beam longitudinal reinforcement for planting reinforcement construction is about 30mm, which is basically arranged according to the requirements of the longitudinal reinforcement spacing of the cast-in-place structure. If the spacing between planting bars is too small, it is easy to cause concrete splitting damage to the structure at the anchorage of planting bars. After adjustment, the beam width for planting reinforcement construction is increased, and the center distance of the planting reinforcement in the beam is controlled at about 100mm to ensure the safety of the structure from the structure.

Beam-column joint reinforcement

The typical column section above the basement roof of this project is 500×500mm, and frame beams are added at the large hole on the second floor. The upper and lower longitudinal bars of the beam are about 8.22 mm. The column section is too small, so the depth of the frame beams cannot reach 25d (d is the diameter of longitudinal rib). If a large number of frame columns are reinforced by increasing the section method, it is more difficult and has a greater impact on the architectural space effect.