Reinforced Continuous T Beams

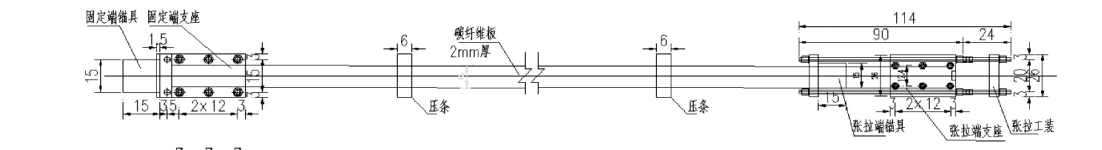

Prestressed Carbon Fiber Strip

Considering that the bridge is on the expressway and there are many passing vehicles, it is required that the reinforcement measures should be easy to implement and the construction period should be short. From the aspects of treatment effect, construction convenience, construction period and cost, the prestressed carbon fiber strip reinforcement method is finally adopted.

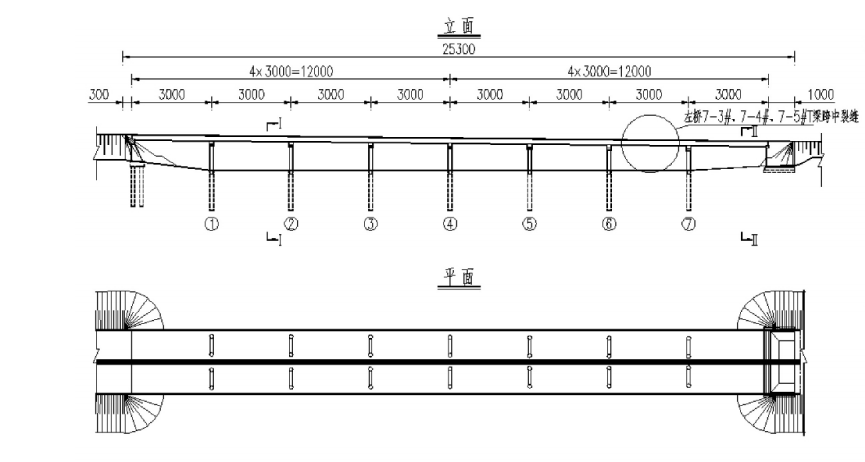

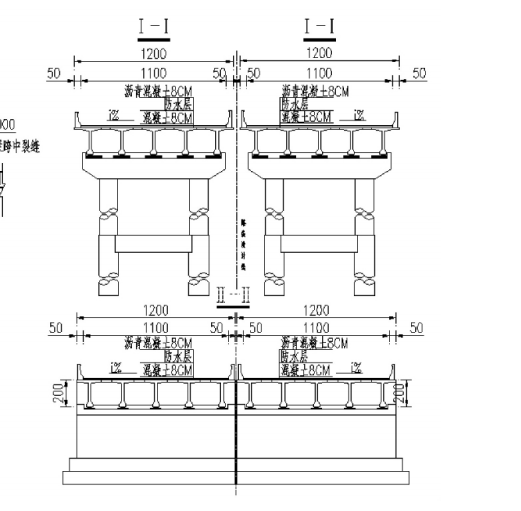

A supporting project is located on the expressway, with a total length of 253m and a span layout of (4×30m+4×30m). Bridge design load: steam-super 20, hanging 120. The upper structure is a prestressed reinforced concrete quasi-continuous T-shaped beam, the support is a plate rubber circular support, and the bridge deck is paved with asphalt concrete. The starting platform is a ribbed platform with pile foundations, the final platform is a U platform expanded foundation, and the bridge piers are column piers. The bridge was completed in October 2005. The layout of the bridge's plane, elevation and cross-section is shown in the figure.

According to the inspection and evaluation report and the visual inspection of the bridge, the main diseases of the bridge are as follows. There are horseshoe transverse cracks, web vertical cracks, oblique cracks, U-shaped cracks in the span of the left bridge 7-5#, 7-4#, 7-3# T beams about 8m in the span, and the crack width is 0.1mm~0.64 mm. The depth of the cracks is measured. Among the 13 larger cracks measured, the maximum crack width is 0.64mm, the crack depth is greater than 30mm (the design value of the steel protection layer), and the maximum depth is 87mm.

Considering that the bridge is on the expressway and there are many passing vehicles, it is required that the reinforcement measures should be easy to implement and the construction period should be short. From the aspects of treatment effect, construction convenience, construction period and cost, the prestressed carbon fiber strip reinforcement method is finally adopted.

The 7-3#~7-5# beams of the seventh span are reinforced and treated, and the specific reinforcement measures are as follows:

(1) For cracks with seam width <0.15mm, adopt surface epoxy sealing method; for cracks with seam width ≥0.15mm, adopt pressure injection sealing method.

(2) After the cracks of 7-3#, 7-4#, 7-5# T beams are treated, a prestressed carbon fiber strip is applied, and a 10cm×0.2cm prestressed carbon fiber strip is added to the bottom and side of the horseshoe.

After the 7th span quasi-continuous T-beam is reinforced with prestressed carbon fiber strip, the stress, flexural bearing capacity and safety factor of the mid-span section before and after the reinforcement are compared. It can be seen that the stress of the strengthened bridge is within the specification limit, and the flexural bearing capacity after strengthening is increased by 13.0%.

The project has been in operation for 2 years after it has been reinforced with prestressed carbon plates. According to the feedback of regular inspections and observation results, the cracks after treatment have not cracked, and no new cracks and other beam diseases have been found, and the treatment effect is good.、