Strengthen Heavy-duty Railway Bridge

Prestressed Carbon Fiber Strip

In order to improve my country's railway transportation capacity to meet the needs of the rapid development of the national economy, the railway industry has vigorously promoted the construction of heavy-haul railways and the heavy-haul enhancement of existing railways.

In order to improve my country's railway transportation capacity to meet the needs of the rapid development of the national economy, the railway industry has vigorously promoted the construction of heavy-haul railways and the heavy-haul enhancement of existing railways.

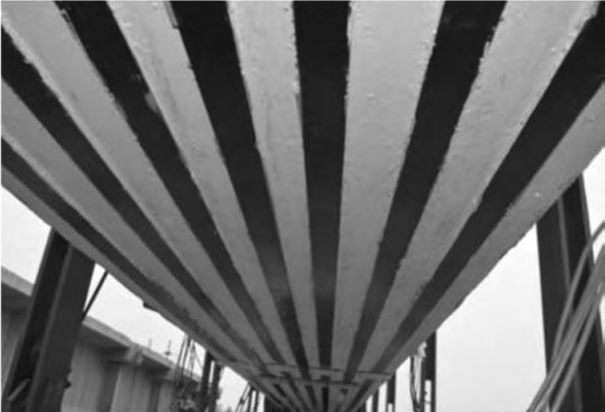

The external prestressed carbon fiber strip reinforcement method is an emerging bridge reinforcement method. The reinforcement method does not affect the normal operation of the line, does not change the original structure, and does little damage to the original structure. The transmission force of the system is clear, and the reinforcement effect is significant, especially suitable for bending reinforcement. The additional anchoring structure is small in size, which is convenient for construction and popularization and application. The anchorage section can be dispersed and arranged flexibly to reduce the anchor point stress, and it can be reliably pasted with the beam body to reduce the live load stress amplitude of the anchor head.

Finally, a carbon fiber strip with a cross-sectional size of 50mm×3mm and a strength index of 2600MPa was selected.

Reinforcement construction process

The main construction procedures of prestressed carbon fiber strip reinforcement of railway bridges are:

①Incoming inspection of materials;

②Detect the position of the steel bars in the beam and identify the position of the prestressed beam in the beam;

③Drilling and slotting at the bottom of the beam;

④Implant chemical anchors;

⑤ The anchoring seat is opened on site;

⑥ Install anchor seat;

⑦Unload the strip, install the anchors, and make the carbon fiber strip assembly;

⑧Fix the carbon fiber strip assembly to the anchor seat;

⑨Apply interface agent on the bottom of the beam, and apply adhesive on the top surface of the carbon fiber strip;

⑩Ten the carbon fiber strip one by one and symmetrically, and lock the nut for anchoring;

11 Paste and fix the carbon fiber strip to the bottom surface of the beam;

12 The anchorage area is grouted to seal the anchor, and the bottom of the beam and surface coating are cleaned.