Bridge Strengthening

Externally Bonding Prestressed Carbon Fiber Plate

After the reinforcement of the prestressed carbon fiber plate, the internal force distribution of the bridge structure has been significantly improved, the bearing capacity of the bridge has been significantly improved, the bearing capacity and deformation requirements have been met, and the reinforcement design goal has been achieved. The mid-span deformation of the beam body under the standard load is significantly reduced.

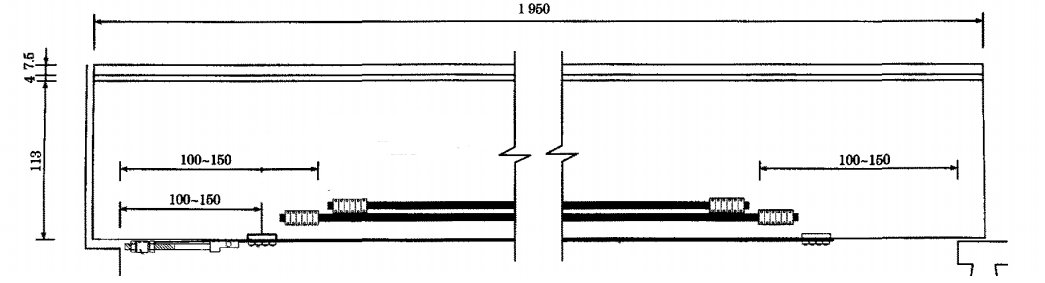

The Jingang Bridge is located on the 106 National Highway in Liuyang City, Hunan Province. It was built in 1963 and has been in service for more than 40 years. The bridge has a total length of 49.5m, divided into 2 spans, with a single span of 19.5m. Each span is composed of 5 pieces of reinforced concrete main T-mode girder and the upper bridge deck. Strong cross-beam connections are set between the T-beams, and the design passing load is 15 to 80 for steam. The relevant inspection department inspected the Jingang Bridge in 2003 and found that the main girder had multiple stress cracks, the bending rigidity was seriously degraded, and the girder had obvious flexural deformation. After the customs clearance department organized an expert survey, the bridge was identified as a dangerous bridge. According to the calculation of the bearing capacity and the load test, it was decided to strengthen and repair the Jingang Bridge according to the passing load standard of steam 20 and hanging 100.

The results of the calculation of the bearing capacity of the front section of the Jingang Bridge show that the flexural bearing capacity of the main girder is insufficient in the area of 3.8 m from the middle to the sides of the main beam. According to the storm analysis of the load test, the difference between its flexural capacity and the target load level is more than 800kN·m. Therefore, it is determined to be reinforced to increase the bending strength. At the bottom of the main beam and at a position about 30 cm away from the bottom of the beam on both sides of the beam ribs, a carbon fiber plate with a cross-sectional area of 140 mm2 and an initial stress of 1000 MPa is attached to each.

Externally Bonding Prestressed Carbon Fiber Plate on Bridge

After the reinforcement of the prestressed carbon fiber plate, the internal force distribution of the bridge structure has been significantly improved, the bearing capacity of the bridge has been significantly improved, the bearing capacity and deformation requirements have been met, and the reinforcement design goal has been achieved. The mid-span deformation of the beam body under the standard load is significantly reduced.