Chemical Plant After Explosion

Appraisal And Reinforcement Treatment Of A Chemical Plant After Explosion

The project has been in use for 6 years since the completion of the reinforcement, and during these 6 years, it has been in good condition. The anti-epidemic performance of the bent frame column after the steel plate enclosing the chicks has been improved. The anti-collision and anti-corrosion effects of the column foot are ideal, the cracks at the corbels are stable, there is no sign of development, and there is no obvious deformation. The crane beam is used normally.

1 Basic situation of the plant

The sulfur warehouse of a chemical group is a two-span (24m span) single-story bent-frame structure warehouse. The warehouse has a total length of 162m and a width of 48m. It uses reinforced concrete columns (column spacing 6m). The roof system uses prestressed roof trusses and large roof slabs, steel roof trusses and color steel roof slabs and arched color steel roof slabs. The plane cloth is shown in Figure l.

In 2008, a sulfur dust deflagration accident occurred suddenly in the sulfur warehouse, and the explosion was more powerful. The plant was seriously damaged. Since the sulfur warehouse is very important in the production process of the entire factory, if it is stopped, it will inevitably cause great economic losses. For this reason, it is required to conduct a safety appraisal of the structure after the explosion while guaranteeing production, and provide a reinforcement treatment plan as quickly as possible.

2 On-site inspection

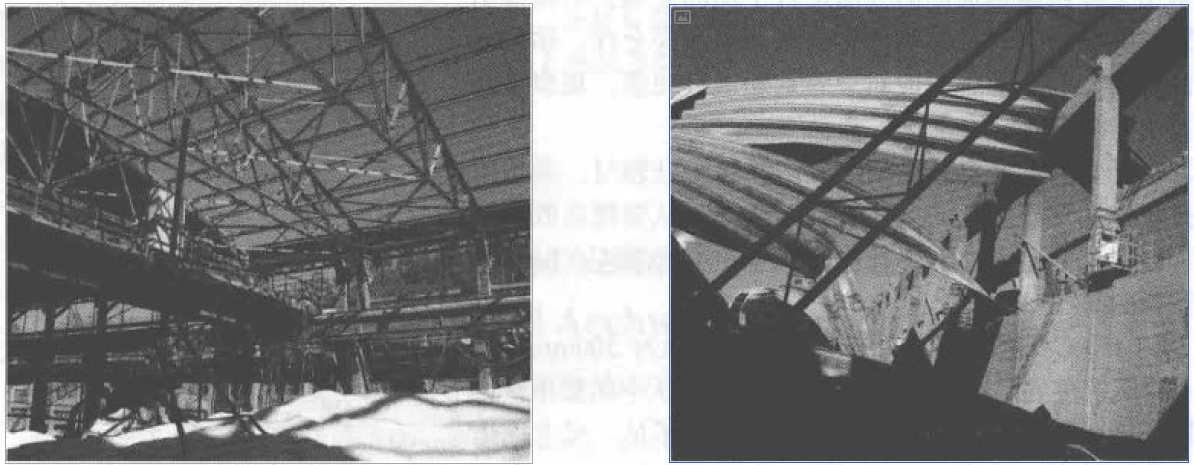

(1) After preliminary site investigation, the core area of the explosion is located near the 8-12/A axis. The basic situation of the site after the explosion was: the dust explosion of the sulfur warehouse damaged the arched color steel roof panels between the 1-32/AB shafts, and the color steel roof panels between the I-10/B -C shafts and 27-32/BC shafts. (The steel roof truss is not damaged)

(2) The damage near the core area of the explosion (8-12/A axis) is the most serious. The concrete columns on the upper part of the corbels 21/B, 20/B and 19/B have been damaged. Four of the concrete columns have 1-2 oblique cracks of different sizes.

(3) The seismic fortification intensity of this area is 8 degrees, and its seismic fortification category belongs to the key fortification category (category B), which shall be appraised according to the seismic appraisal method of category A buildings. After testing, the diameter of the box reinforcement at the corbel of the bent column between the B-C/9-28 axis is </)8, and the spacing is 300mm. Does not meet the requirements in the "Standard for Seismic Appraisal of Buildings" (I) (GB 50023 2009)

(4) After inspection, there is no abnormality in the foundation of the factory building, the tilt of the bent column and the deflection of the roof truss are not abnormal.

3 Analysis and treatment plan

(1) The explosion caused cracks on the 21/B, 20/B, and 19/B columns, although the four corners of this column have been reinforced by the method of encasing angle steel. However, the cracks caused by the explosion have a large width, which has affected the bearing capacity and safety. The cracks must be treated by pouring. After treatment, the cracks should be regularly observed to observe whether there are signs of increase and continued deformation.

In order to ensure that the repair glue completely fills the crack cavity, the glue hole must be reserved during the pouring process, and the low pressure and low speed method should be used for pouring, starting from the lowest pouring point of the crack and pouring upwards. When the repair glue penetrates to the upper relief point, it can be moved to a new injection point for infusion.

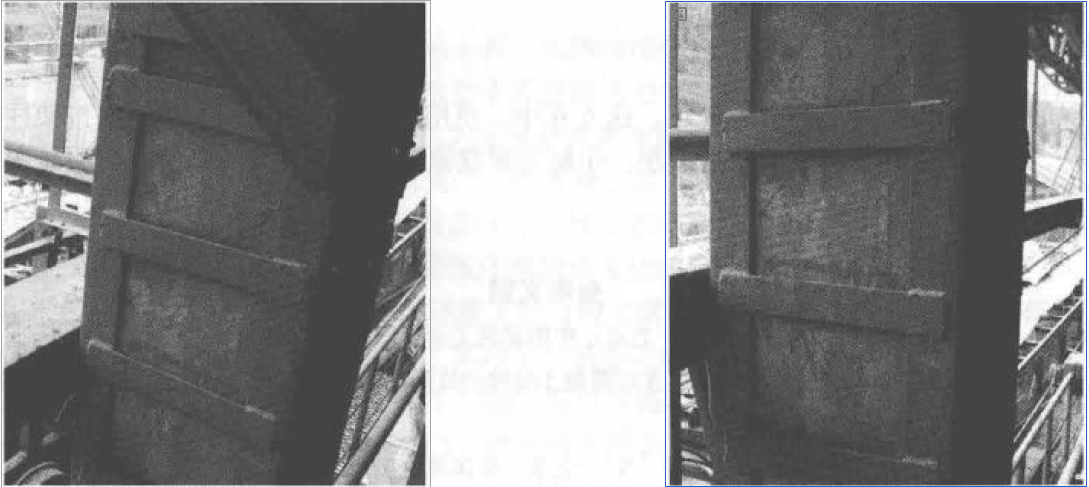

(2) B-C/9-28 The spacing between the bent column ribs between the axes is 300mm, which does not meet the requirements of the "Building Seismic Appraisal Standards" (GB 50023-2009). The spacing between the ribs of the bent frame column is too large, resulting in insufficient ductility and resistance performance, so it can be considered to increase its volume reinforcement ratio. Considering that during the treatment process, the factory building cannot stop production, the construction surface should not be too large, and wet work should be avoided. This time, the steel plate enclosure method is used for reinforcement. This method is fast and has little impact on production. Taking into account the requirements of corrosion resistance, cement-based grouting is used as an adhesive, which has the characteristics of high strength, no shrinkage, no aging, and high temperature resistance.

In addition, when loading and unloading sulphur, there are often loading vehicles driving in, which often cause collisions to the column foot of the bent frame. During this reinforcement, an anti-collision angle steel was installed at the foot of the column to protect it. And put 30mm thick cement mortar in this range to strengthen the anti-corrosion effect.

4 Conclusion

The project has been in use for 6 years since the completion of the reinforcement, and during these 6 years, it has been in good condition. The anti-epidemic performance of the bent frame column after the steel plate enclosing the chicks has been improved. The anti-collision and anti-corrosion effects of the column foot are ideal, the cracks at the corbels are stable, there is no sign of development, and there is no obvious deformation. The crane beam is used normally.