Bonded Steel Reinforcement

Bonded Steel Reinforcement in Underpinning of Concrete Columns

There are not many cases of underpinning concrete columns using sticking steel technology. Due to the large thickness of the steel plate, the post-injection method is used for construction.

1 Project Overview

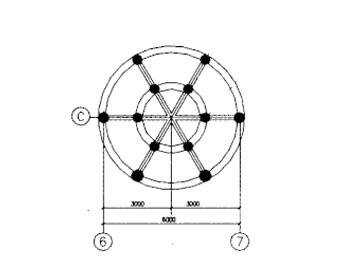

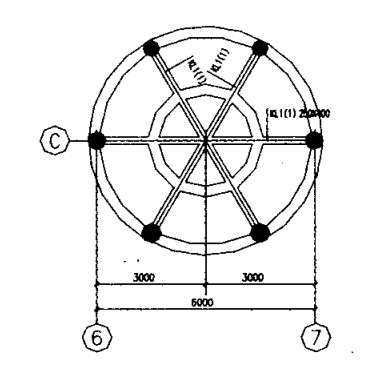

A circular sightseeing ladder is composed of six cylinders in the inner circle and six cylinders in the outer circle. The cylinders are connected by three cross beams (see Figure 1). The clear height of the roof layer is 2.5m. In order to expand the use space and make it convenient for tourists to go sightseeing, it is necessary to remove the six columns in the inner ring of the roof layer. The removal of the columns will redistribute the force of the original structure, resulting in insufficient bearing capacity of the original roof beams, so the roof beams need to be reinforced .

2 Reinforcement scheme

2.1 Reinforcement scheme selection Because six columns are removed, three cross beams with insufficient bearing capacity need to be reinforced. Two schemes are proposed to be considered:

(1) Enlarging the section method to strengthen three cross beams. If the enlarged section method is used to strengthen three cross beams, according to the calculation results, it is necessary to add a row of longitudinal reinforcement at the bottom of each beam. Then there will be three rows of cross longitudinal bars at the mid-span intersection of the three cross-strengthened beams. In addition to the spacing between the steel bars and the thickness of the concrete protective layer, the bottom of the beam must be expanded by at least 20cm. This greatly reduces the net height of the floor and cannot meet the usage requirements.

(2) The three cross beams are strengthened by the method of sticking steel plates. However, the steel plate is attached to the bottom of the three cross beams to strengthen the steel plate, and the steel plate is relatively rigid. The three layers of steel plates in different directions cannot be overlapped and pasted at the intersection.

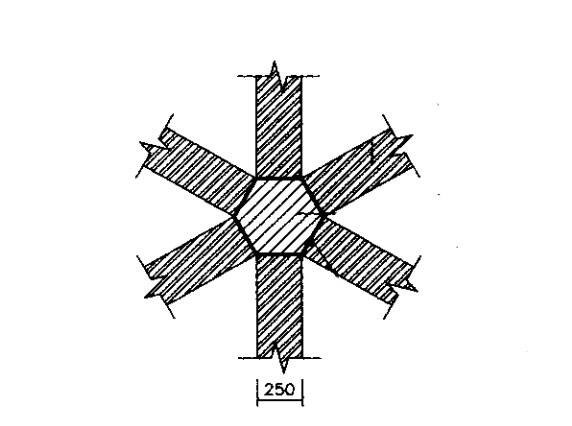

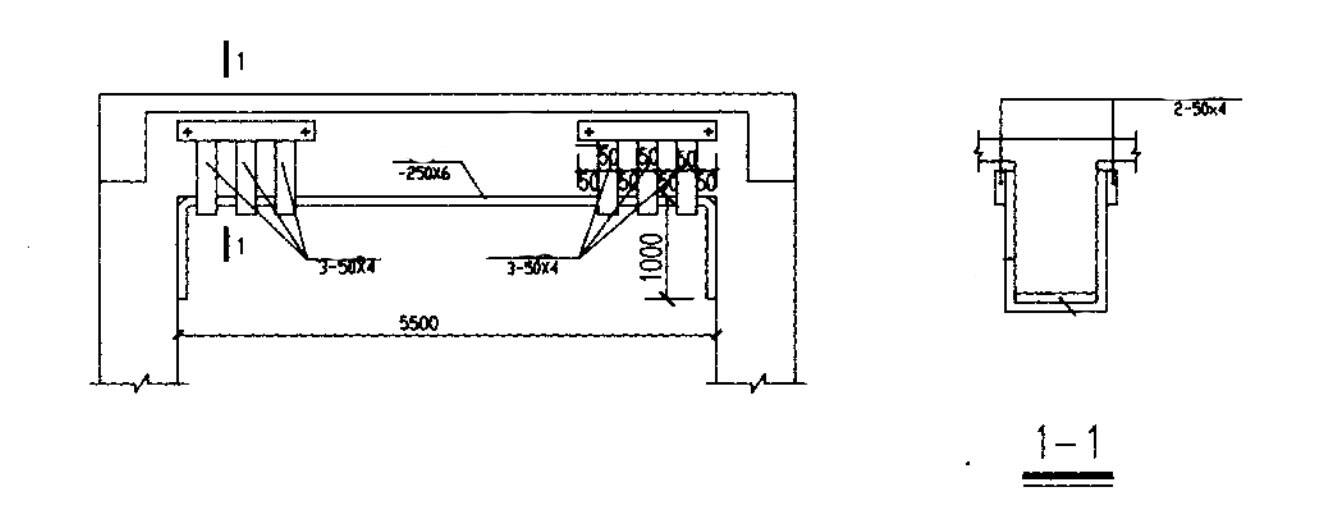

After consideration, it was decided to adopt the sticking steel reinforcement scheme, and the overlapping steel sticking problem at the intersection was solved according to the following scheme. A regular hexagonal steel plate block is made (as shown in Figure 2), and the steel plates of each beam section are effectively welded to it. If the traditional steel plate pasting method is adopted, six steel plate segments and hexagonal steel plates need to be welded into a whole, and then glue is applied to the steel plate, and finally the whole is lifted to the bottom of the cross beam to be pasted. However, the six welded steel plates are heavy and difficult to construct. If the construction is pasted in sections, glue the hexagonal steel plate first, and then use glue anchor bolts to anchor the hexagonal steel plate at the intersection of the three beams. Glue is applied to each steel plate, and then welded with the hexagonal steel plate. However, the high temperature generated by welding will be transmitted to the structural adhesive through the steel plate, and the phenomenon of melting glue will occur, which greatly reduces the bonding effect of the structural adhesive. Finally, it was decided to use post-injection method to stick steel construction. The post-injection method is used to stick steel construction, that is, the hexagonal steel plate and the six steel plates are anchored to the bottom of the beam to be reinforced and welded into a whole at the same time, and finally glue is injected to achieve reinforcement.

2.2 Cylinder support unloading

Before the column is drawn, a jack and a large-diameter steel pipe are used to support and unload the six cylinders in the inner ring (see Figure 3 for details), and two sets of supports (jacks and large-diameter steel pipes) on both sides of each cylinder. The two steel pipes between the two columns are fixed by cross bracing to ensure the horizontal stability of the steel pipe. The upper and lower ends of the steel pipe are welded and sealed with 8mm thick, 250mmX250mm rectangular steel plates to increase the contact area between the steel pipe support and the beam and jack. After the support is made, the concrete column is chipped away. In order to reduce the damage to the original beam in the process of removing the concrete column, a percussion drill is used to drill the concrete at the top and bottom of the column (about 10 cm each). Then cut off the concrete from top to bottom. When the concrete is cut off, the steel bars of the original column are cut off.

2.3. Beam sticking steel reinforcement

At the intersection of the cross beams, fix the pre-made hexagonal steel plates with glue anchor bolts. Then, glue anchor bolts are used to anchor the six steel plates under each beam section, and at the same time, each steel plate and the hexagonal steel plate are welded to form a whole. A 3mm~5mm thick gap is reserved between the steel plate and the concrete beam. The six sides of the hexagon are respectively welded to the steel plate of each beam section, and the steel plate of each beam section is fixed on the concrete beam with glue anchor bolts. Paste "U"-shaped steel hoops at both ends of each beam for additional anchoring

Concluding remarks

There are not many cases of underpinning concrete columns using sticking steel technology. Due to the large thickness of the steel plate, the post-injection method is used for construction. In addition, the rigidity of the steel plate is large, and instead of superimposing and pasting at the intersection, a hexagonal steel plate is used at the intersection to connect the six steel plates of each beam section to form a whole. The project has been put into use for more than half a year, and it has experienced multiple typhoons. No new cracks have been found in the beams and columns. The working conditions are good. Practice has proved that the reinforcement project of this example is successful. It can be predicted that bonding steel technology will be more widely used in concrete structures.