Application of Steel Plate Bonding Technique Combined with Carbo

The factory was retrofitting into a mall

Application of Steel Plate Bonding Technique Combined with Carbon Fiber Cloth to Concrete Beam

Project Overview

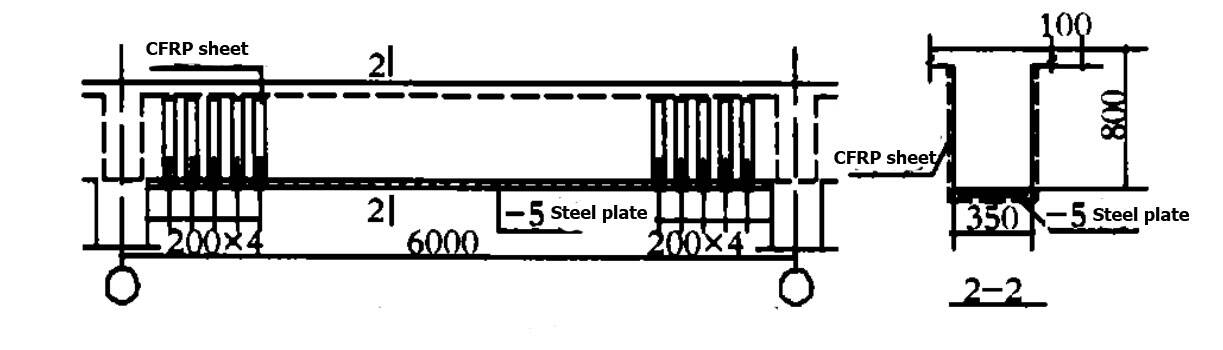

Shanghai Eurasian Yiming Mall was transformed from the factory building of the original rubber factory. The original building is a 7-story frame structure with a beam span of 6m. Due to the changes in use functions, the original structure should be reinforced according to the reconstruction plan, including the reinforcement of beams, slabs, and columns. A variety of reinforcement techniques are used in the design of the reinforcement scheme, among which the beams are reinforced by bonding steel technology combined with carbon fiber reinforcement. In addition to the original construction drawings, the design also refers to the physical structure inspection results of the old concrete. The reinforcement steel plate is made of 16 manganese steel. According to the results of the check calculation, the design adopts 4mm or 5mm steel plate and HM-120 building structural glue. When the shear force of the beam to be reinforced is insufficient, HM-20 unidirectional carbon fiber cloth (CFRP) and corresponding resin reinforcement are used (see Figure 1).

Reinforcement process

Reinforced beam concrete surface and steel plate surface treatment-reinforcement member unloading (lifting by jack)-adhesive preparation-coating glue-sticking steel plate-fixed pressure-curing-carbon fiber wrapping-unloading support and removal-sand blasting and anti-corrosion painting

Construction attention points

Finished product protection

(1) Protect the treated concrete base, and enclose the concrete surface to be dried with enclosures to prevent dust from falling on the surface.

(2) For the protection of the rubber surface of the primer, depending on the construction environment, cover it to prevent dust if necessary.

(3) The cut carbon fiber sheets must be stored carefully to avoid wrinkles, and do not get water or dust. Keep away from electrical equipment when cutting to avoid short circuits caused by carbon fiber shavings

Key points of safe construction

(1) Due to the large amount of reinforcement and the tight construction period, attention should be paid to the division of work sites during construction arrangements. There should be a certain safe distance between electric welding and gas cutting operations and gluing operations.

(2) The scaffolding for indoor operation shall be erected by scaffolders in accordance with regulations, and shall be safe and stable to ensure the safe operation of workers. .