Strengthening Reinforced Concrete Column

Column Strengthening By FRP Wrap and Steel Plate

Strengthening Reinforced Concrete Column By FRP Wrap and Steel Plate

Project Overview

A certain building was built in the 1950s. During the use of the basement, the acid battery was stored, causing serious corrosion and cracking on the surface of the concrete vertical members. After careful inspection on site, the carbonization depth of some basement frame columns is between 25mm-35mm. Part of it has been carbonized to the column’s longitudinally stressed steel bars, and the corrosion is severe. About 50% of the column concrete protective layer has wide cracks along the reinforcement. More than 25% of the steel bars are exposed and severely corroded. The maximum cross-sectional area loss rate after steel corrosion is 30%.

The user requires equal-strength reinforcement of the corroded frame column's stressed steel bars, and must ensure that the normal operation of the equipment will not be affected during the construction and reinforcement of the column, and at the same time consider saving reinforcement costs.

Selection and implementation of reinforcement plan

As there are communication cables and power equipment at the construction site, these equipment cannot be moved, and the parts close to the equipment cannot be welded. Due to the limitation of site and reinforcement cost, the research decided to adopt the following scheme. Reinforced concrete sleeve reinforcement is used in places far away from the equipment with little impact. For places where there is no construction site, the outsourcing angle steel reinforcement method is adopted. FRP wrap reinforcement is used for frame columns that have no operating space and cannot be welded.

Before reinforcement, the loose and fragile concrete in the original structure should be chiseled out, and the honeycomb, pitted surface and holes of the original structure should be removed and repaired with epoxy mortar. The structural crack width >0.2mm is repaired by low pressure pouring method to restore the concrete strength. For the cracked surface concrete that has weathered and crisp layer, carbonized rust cracked layer and serious oily layer, it should be cut out before pouring construction. Use surface sealing measures for structural crack width ≤ 0.2mm.

Now give a brief description of the technical requirements of various construction schemes

1 Construction method of reinforced concrete sleeve reinforcement

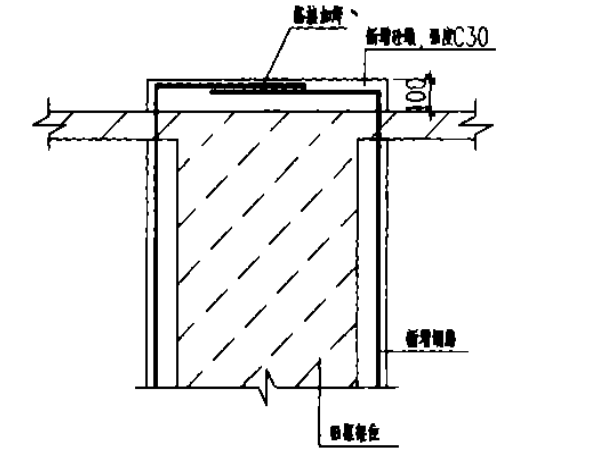

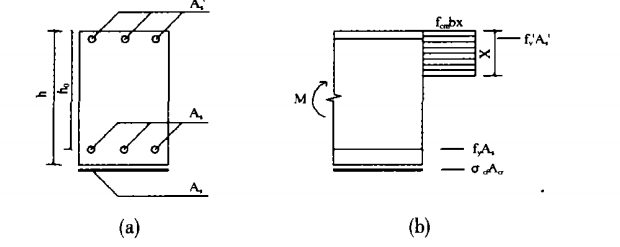

The enlarged section method is the simplest and most economical reinforcement scheme. The disadvantage is that it needs to be reinforced from the foundation, the construction period is long, and the self is heavy. When removing the original structural concrete protective layer, a heavy hammer must be used to strike it lightly, and a sledgehammer must not be used to reduce the damage or fracture of the frame column beam caused by the striking vibration. The corroded steel bars must be cleaned with phosphoric acid and shall not be cut without authorization. The contact surface between the fresh surface of the original structural concrete and the newly poured concrete is roughened and water is used. Clean it in the middle and apply adhesive on the surface. See Figure 1 for details of the method of anchoring the reinforcement of frame columns. At the contact surface between the new column concrete and the original frame column, short anchor bars will be added every 300 vertically and every 200 horizontally. The maximum water-cement ratio of newly added concrete should not be greater than 0.55, the minimum cement consumption should not be less than 300kg per cubic meter, and the thickness of the protective layer is 35.

2 External angle steel reinforcement method of concrete truss web members

This kind of reinforcement method is convenient to obtain materials, low cost, simple construction, and the shortcomings require regular maintenance. Our treatment is to brush the anti-corrosion cement mortar surface layer outside the outsourcing angle steel.

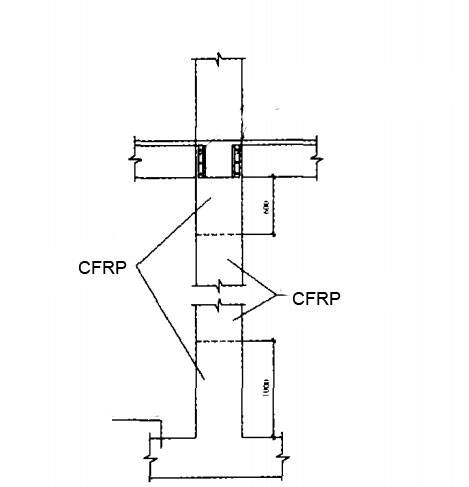

3 carbon fiber reinforcement column

Carbon fiber has high strength, light weight, good corrosion resistance, simple and fast construction process, and has almost no effect on the original structure when used for reinforcement and reinforcement, and has good reinforcement and repair effects and durability. Greatly improve the bending, shear, torsion, tensile bearing capacity and seismic performance of the reinforced component, enhance the ductility and stiffness of the component, and improve the force performance of the component. Here we mainly deal with column bending and shear reinforcement.

Concluding remarks

The above reinforcement methods can strengthen the concrete structure, which can increase the bearing capacity, enhance the seismic capacity, and improve the seismic performance. Reinforcing concrete structures in corrosive environments can enhance their corrosion resistance, prevent and reduce the occurrence of cracks, and improve the durability and reliability of the structure. Moreover, these methods have their own advantages and disadvantages. In short, these reinforcement methods are convenient to obtain materials, moderate in cost, simple and quick to construct, and have little impact on the original structure. Designers can use them flexibly in applications and have broad application prospects.