Column strengthening-Reinforced concrete pouring reinforcement

Column strengthening-Reinforced concrete pouring reinforcement

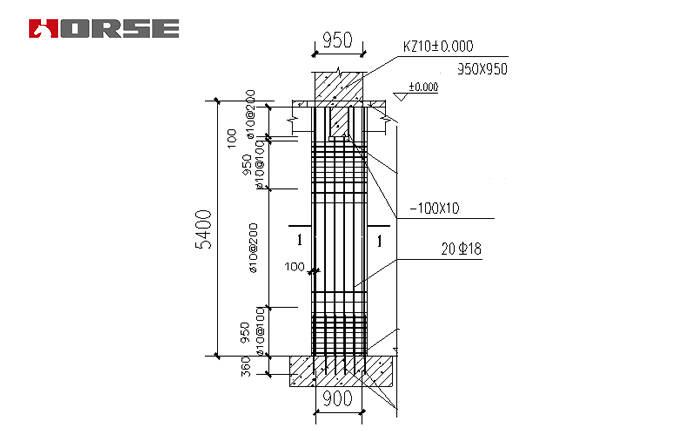

Due to the redesign of the upper part of the project, the function of the project is changed and the height of the house is increased. After testing, 3 KZ10 (6/2-4; 9/E; 9/G) -5.400 ~±0.000 parts are strengthened, and reinforced concrete reinforcement scheme is adopted to strengthening the column.

Project overview

Due to the redesign of the upper part of the project, the function of the project is changed and the height of the house is increased. After testing, 3 KZ10 (6/2-4; 9/E; 9/G) -5.400 ~±0.000 parts are strengthened, and reinforced concrete reinforcement scheme is adopted to strengthening the column.

Construction preparation

(1) compiling a practical and feasible construction plan. Because the construction quality of columns is closely related to the quality of structures, we must attach great importance to the reinforcement work of columns and strictly enforce the construction plan.

(2) assess the professional qualification of professional teams.

(3) carry out detailed and comprehensive technical and safety disclosure to the operators.

(4) strict control of the materials used for structural strengthening.

Construction process

1. Clean up the site

The wall and the ridge of the 3 KZ10 needed to be strengthened from the edge of the column to the 1.5m range should be removed (a total of 7 walls, 2 rows of ridge), and the 500mm concrete ground between the columns and the shear walls should be chiseled. Due to the accumulation of water in the original underground room, after the wall is dismantled, the 2m to 2.5m area around the column is blocked by cement to form a water separation wall, and the water in the block is pumped clean. Clean up until the structure is exposed.

2. column treatment

The original column surface and beam surface have been plastered, so the plastering layer is removed first, and the surface of the column and the surface of the beam from the 20cm range of the column are removed by 1-2cm.

3. Post installed anchor and stick steel plate

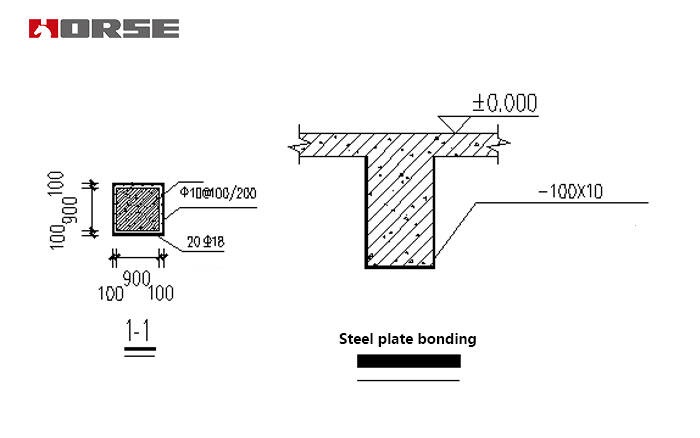

Each column is planted on the floor with a depth of 20 (18) and a depth of 360mm (at the same time ectopic pull-out test). The exposed length is 800mm, and then the main reinforcement is lapped. Each beam that intersects the column is treated with 100 - 10 flat steel in the position close to the column, and the L100 - 10 reinforced angle steel is welded to the main reinforcement at the bottom of the beam.

4. Reinforcement binding, template support and concrete pouring

In the bottom plate industry, 20 of the 18 reinforced bar is tied up and the main reinforcement is 20 mm 18. The type, method, spacing and template dimensions of the stirrups are shown in the attached drawings. In the upper part of the template, the slanting die is adopted, the steel pipe hoop and the inclined bracing are strengthened by the template. The first steel pipe hoop is arranged along the bottom of the column to the top 300mm, and then one to the top is arranged every 500mm. Each steel pipe hoop is reinforced by inclined braces or braces. C45 concrete (maximum particle size is not more than 25mm, the collapse degree is controlled in 17-20cm), the diameter of 150mm circular hole (each one of column four angles) and 400 x 400 hole on the 1.8m and 3.6m high formwork on the ground are put up in advance. Vibrate at the outside of the template when vibration is vibrated.