Repairing Bridge Cracks

Crack injection adhesive

Select language

Crack injection adhesive

Repairing bridge cracks with crack injection adhesive, the crack resin and its supporting materials have good performance, easy to use, nontoxic, non irritating odor, on-site civilization, and safe.

Project overview

The upper frame of the K1+722 dash high bridge is a continuous prestressed concrete T beam with 9*30 meters (left) and 8*30 meters (right amplitude). The lower structure abutment adopts a column table, pile foundation and pier foundation.

The main bridge is K5+192.853 prestressed concrete continuous steel frame bridge with 64+120+64m prestressed concrete bridge. The main bridge of Ma Wu high speed bank is constructed as 7*40m first simple support and continuous prestressed concrete T beam. The Cang Yu high-speed shore bridge is composed of 6*40m first simple support and continuous prestressed concrete T beam, the lower structure pier is column pier, and the foundation is expanded in addition to the 0# abutment. The main foundation and the rest are bored piles.

K7+852 folu River Bridge, with 7*30 meter (left amplitude), 8*30 meter (right amplitude) and continuous prestressed concrete T beam, the lower structure abutment adopts U abutment, which is excavated to expand the foundation, the pier is column pier and pile foundation.

Cause analysis

The reasons for slight cracks in bridge concrete are mainly as follows:

High strength concrete is used in bridge concrete, and the shrinkage and creep of concrete are more influenced by shrinkage and creep.

During the construction period of the bridge, when the site is in rush hour and the concrete strength is not up to 100%, cracks will appear in the next part of the site.

In site construction, there is not timely and untimely maintenance, resulting in excessive temperature difference between inside and outside of concrete, resulting in cracks.

Solution:Repairing Bridge Cracks With Crack Injection Adhesive

1.crack inspection

2.crack treatments

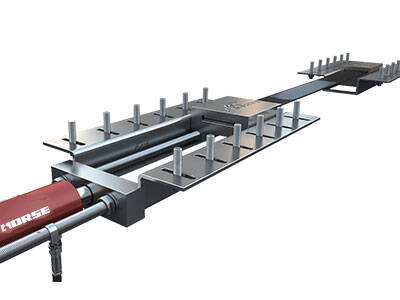

3.embed pouring glue nozzle

4.seal crack

5.sealing check

6.prepare pouring crack adhesive

7.pour glue

8.conservation

9.examination and test

Website Map | Corporate | Contact | Privacy