Summary: Brand:HORSE CONSTRUCTION; Types:carbon fiber fabric; Place of production:China; Specification:200G, 230G, 300G, 530G, 600G.

Become a distributor of carbon fiber fabirc

Brand:HORSE CONSTRUCTION;

Types:carbon fiber fabric;

Place of production:China;

Specification:200G, 230G, 300G, 530G, 600G.

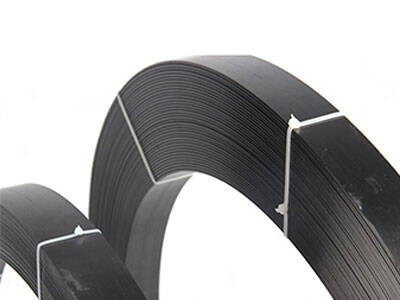

HM UD Carbon Fiber Fabric

Carbon fiber not only has high strength and high elasticity as carbon fiber, but also possesses the characteristics of light self-weight and durability. Beginning from the application associated with the aviation and astronomy, to the use of sporting goods and machinery industry. In recent years, as the substitute of reinforced materials of concrete structures, it was widely used in the seismic reinforcement fortifications of highway, railway and bridge piers, tunnels, and buildings.

Advantages OF HM Carbon Fiber

1, Select the international high-quality aviation grade yarn, keep every carbon fiber yarn length over 5000 meters to ensure the continuity of the carbon fiber fabrics without damage raw fiber.

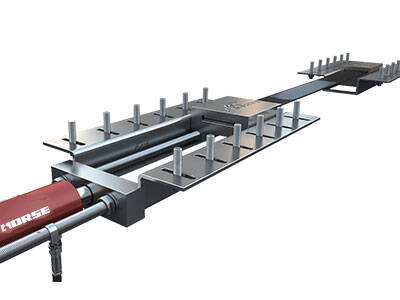

2, 5 world leading Germany imported intelligent production line. Point to point active wefting insertion, no damage or broken filament in the whole production process.

3, Independent developed constant tension system, ensures every bunches of raw fiber keeping constant tension. With low dispersion, high strength, stable properties, the qualification rate by national authority testing organization is 100%.

4, The carbon fiber fabric is woven evenly and smooth, moderate soft, good suitability with the impregnated adhesive, easy to impregnate, total adhesive usage used to 15% less than other suppliers’, and the hollow issues used to 80% less than other suppliers’.

5, Annual capacity of quality carbon fiber fabric is 5 million square meter, and keep daily stock over 100,000 square meter to guarantee any project’s demands.

Product Characteristics:

Light self-weight, can operate in a narrow and small space, not affect the normal use of the houses in the construction;

High strength, can be used in bending, closed hoop and shear reinforcement flexibly;

Has the flexibility, can wrap components with complex shape;

Suitable for surface of various components (beams, columns, ventilation tube, pipe, wall);

Anti-acid alkali and other chemical corrosion and rugged environments (have no environmental pollution in themselves);

Long storage life, allow long operational deadline;

High strength, high modulus;

Can be the substrates of concrete, masonry structure, wood structure, and many other structures;

High temperature resistance, creep resistance under permanent load, corrosion resistance and good seismic resistance performance

Application Range

Load increase:

1.the use load of commercial building increase

2.the tonnage of bridge vehicles increase

3.the installation of heavy equipment industrial buildings

4.vibrational structure

5.change building function

Improve structural state

1.reduce the deformation

2.reduce the stress of the original structure

3.the crack reinforcement

Seismic retrofitting

1.columns reinforcement

2.masonry walls reinforcement

3.beam slab reinforcement

Change structural system

1.change the position of wall and column

2.open floor slab holes

Structure encounter damage

1.the aging of materials in construction

2.the corrosion of steel bars

3.the collision of vehicles

Correct mistake in design or construction

1.lack of reinforcing bars

2.lack of member cross section

3.concrete without enough strength

Technical Parameters

Model | Specification | Strength Grade | Thickness |

HM-20 | 200g/m2 | High strength Grade I | High strength Grade II | 0.111mm |

HM-23 | 230g/m2 | High strength Grade I | High strength Grade II | 0.128mm |

HM-30 | 300g/m2 | High strength Grade I | High strength Grade II | 0.167mm |

HM-43 | 430g/m2 | High strength Grade I | High strength Grade II | 0.240mm |

HM-45 | 450g/m2 | High strength Grade I | High strength Grade II | 0.250mm |

HM-53 | 530g/m2 | High strength Grade I | High strength Grade II | 0.294mm |

HN-60 | 600g/m2 | High strength Grade I | High strength Grade II | 0.333mm |

Width:100mm、150mm、200mm、250mm、 300mm、500mm, Other width can be customized. |

Weave: Unidirectional |

Appearance: Black |

Performance Indexes

Project Name | Ι grade technical index | ΙΙ grade technical index |

Standard Value of Tensile Strength(Mpa) | ≥3400 | ≥3000 |

Tensile Elastic Modulus(Mpa) | ≥2.4×105 | ≥2.1×105 |

Elongation(%) | ≥1.6 | ≥1.5 |

Bending Strength(Mpa) | ≥700 | ≥600 |

Interlaminar Shear Strength (Mpa) | ≥45 | ≥35 |

FRP with Base Materials Bonding Strength(Mpa) | ≥2.5Mpa, concrete cohesion damage |

Density(g/cm3) | 1.8 |